Formnext, one of the leading additive manufacturing trade shows, will host Horizon Microtechnologies and Boston Micro Fabrication (BMF) this year in Hall 11.1, Booth B38. Horizon has successfully commercialized its microstructure coating processes and now offers a new range of technologies for the 3D printing market.

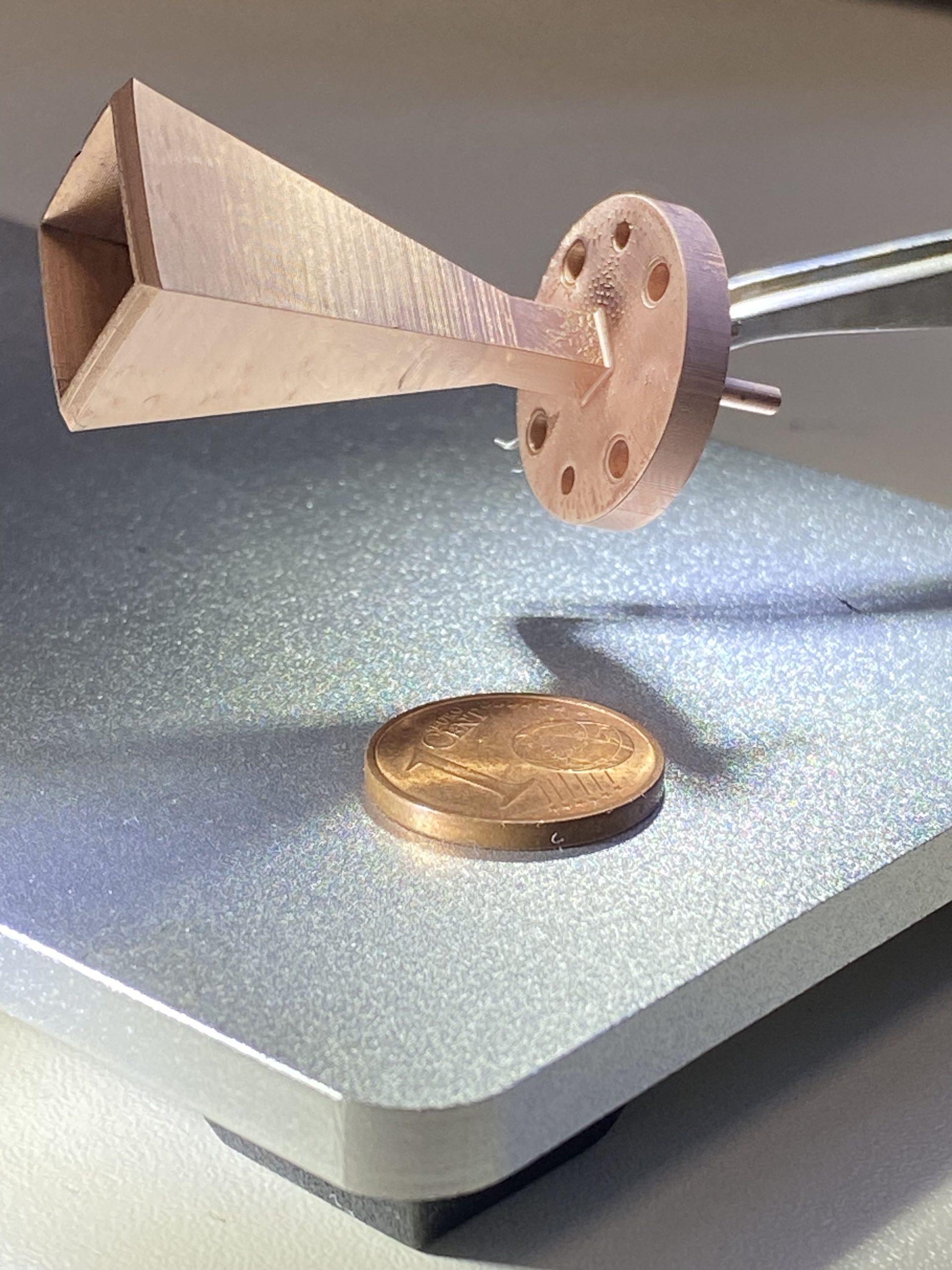

Horizon focuses on the optimization of parts produced by micro-AM (additive manufacturing). The company’s innovative coating processes enable the integration of non-metallic conductive, environmental and metallic coatings on polymer micro-AM parts. This opens up applications and sectors that were previously unable to fully exploit AM due to limited material options.

Andreas Frölich, CEO at Horizon says, “We are delighted to be at Formnext, and also delighted to be on the booth with BMF, from whom we recently purchased a microArch S240 micro AM machine. Our company has a unique understanding of the micro-AM based 3D microfabrication process chain, and while we provide a suite of post-build coating processes, our ability to now build parts in house on the BMF machine allows us to provide a complete technology infrastructure in-house. This means customers can benefit from a truly vertically integrated solution from design to delivery. It also speeds up the development of our post-build coating technologies which will have a profound impact on industry by continually broadening the use of micro-AM into different application areas.”

BMF is known for its high-resolution micro-AM platforms suitable for both prototypes and final products. One outstanding feature is the patented Projection Micro Stereolithography (PµSL) process. This combines the advantages of digital light processing (DLP) with those of stereolithography.

Frölich continues, “At Formnext we want to talk about real applications with customers, and we will have parts on the booth which show the versatility of our coating processes, and the intricate parts that can be made on the microArch S240. Horizon can act as an end-to-end product development and contract manufacturing partner, influencing the design of micro AM parts to optimise them for end-use functionality and also optimise them for the application of our proprietary coating technologies. We can wholly or selectively coat micro-AM parts with a non-metallic conductive layer, add environmental resistance to parts enabling the creation of microscale devices that are more durable, reliable, and better suited for use in harsh environments — such as in the presence of aggressive chemicals and/or high temperatures, and can wholly or selectively coat micro-AM parts with copper.”

Finally, interested parties can learn more about the future-proof technologies in the field of micro-AM in Hall 11.1, Booth B38 at Formnext. Horizon’s team will be on hand to discuss the many possible applications of their post-build coating processes.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.