Berlin-based developer and manufacturer of large scale 3D printer BigRep ONE has unveiled two new devices at formnext this week: BigRep STUDIO and BigRep TECH in cooperation with Kühling&Kühling.

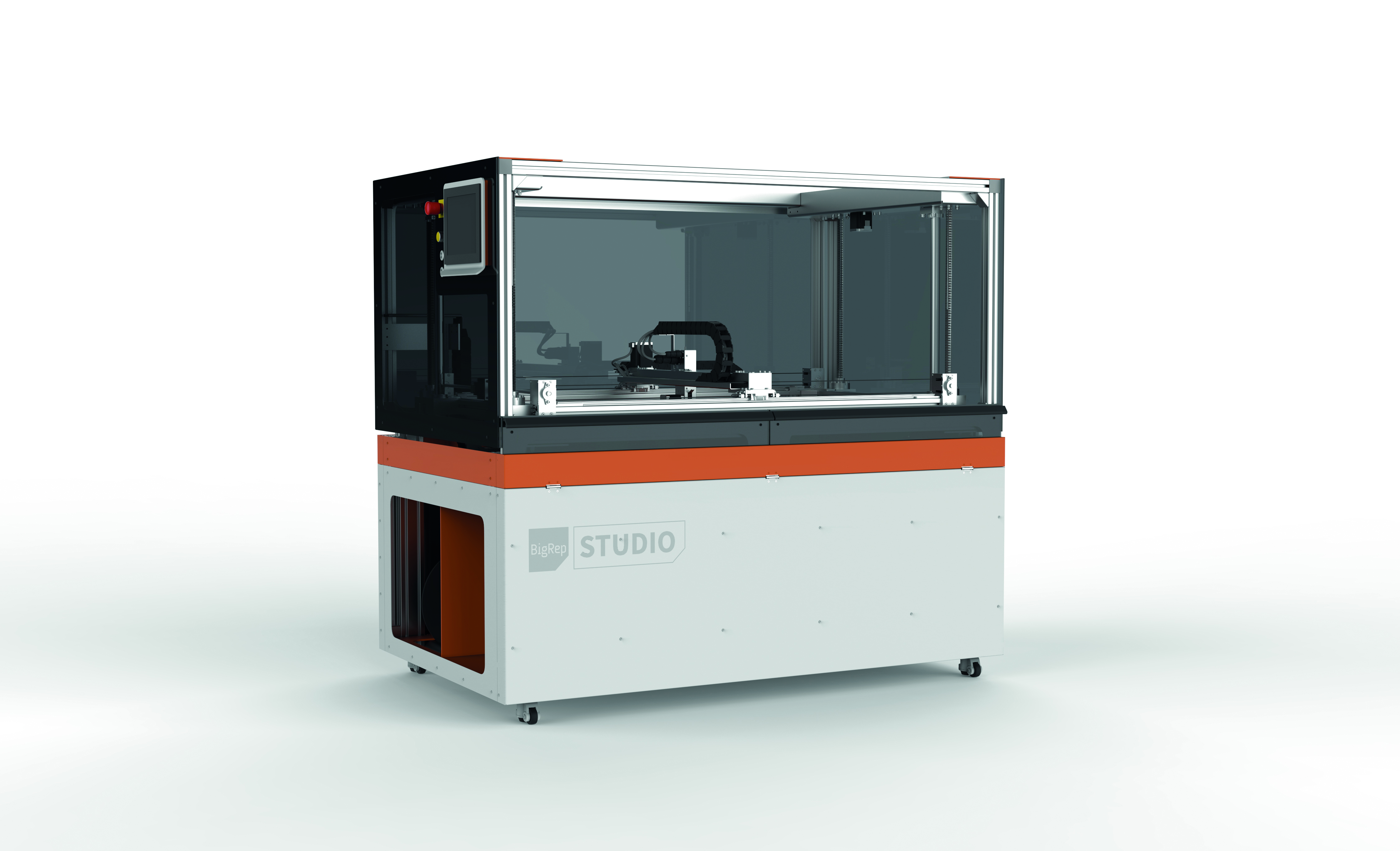

The new and more compact BigRep Studio FDM printer is considerably smaller and lighter in terms of size and weight as well as build volume compared to the BigRep ONE. It is easily transported and installed, and is primarily designed to be used for development and manufacturing purposes in corporate and educational environments. The printer has an installed extruder with a 0.6 mm nozzle for fast and high-precision 3D printing, utilizing the high-temperature filament PRO-HT. The enclosed build chamber offers additional safety features.

Technical specifications BigRep Studio:

- Technology: FDM

- Build volume: 500 x 1000 x 500 mm

- Positioning accuracy: 300 microns

- Extruder: single extruder with 0.6 mm nozzle

- Materials: PLA, PETG, PRO HT

- Size: 1022 x 1660 x 1500

- Weight: approx. 250 kg

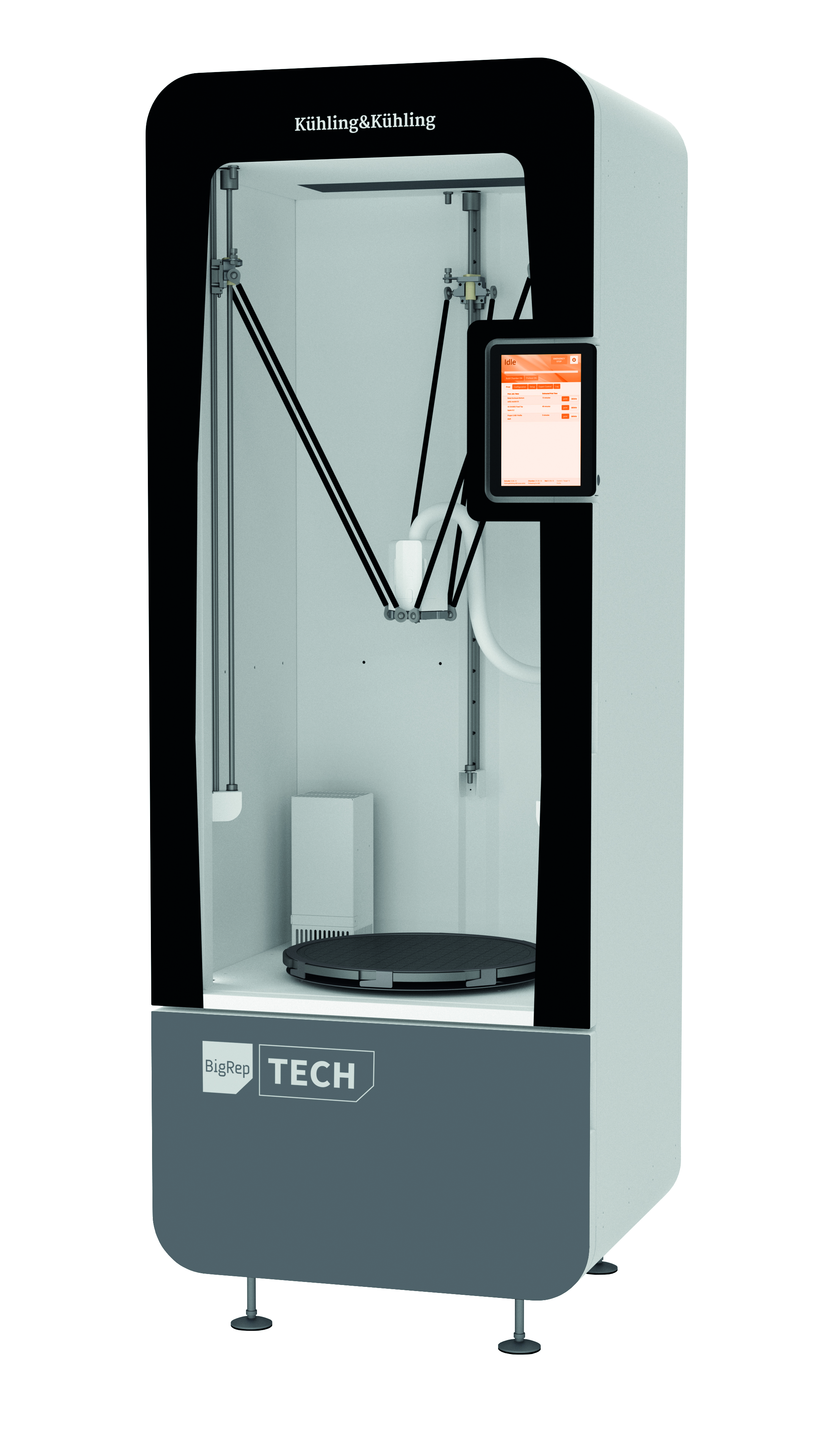

In a cooperation with Kühling&Kühling, BigRep has also launched the VP 75 in its own design as BigRep Tech, developed and manufactured by Kühling&Kühling.

The delta 3D printer it is designed for high-end 3D printing solutions such as medical technology, due to its printing precision and the high-performance, high-tech print materials used. The “BigRep Tech” is the first 3D printer in BigReps’ product portfolio which can process technical plastic polycarbonate. This plastic is characterized by incredible strength, high impact resistance, robustness and hardness, and is ideally suited for applications in the med-tech field.

The delta 3D printer it is designed for high-end 3D printing solutions such as medical technology, due to its printing precision and the high-performance, high-tech print materials used. The “BigRep Tech” is the first 3D printer in BigReps’ product portfolio which can process technical plastic polycarbonate. This plastic is characterized by incredible strength, high impact resistance, robustness and hardness, and is ideally suited for applications in the med-tech field.

Technical specifications BigRep Tech:

- Technology: FDM

- Build Volume: ø400 x 600 mm

- Print head: high-performance print head for engineering-grade materials

- Build chamber: Precisely heated and controlled build environment

- Build surface: Vacu-Flat simple exchange and fixation technology

- Materials: PC filaments tested extensively, more materials to be released soon

- Dimensions: 800 x 740 x 2200 mm

- Weight: approx. 250 kg

René Gurka, CEO of BigRep says: “We are very pleased to announce our cooperation with Kühling&Kühling. The two companies share the same quality and service philosophy. Thanks to our worldwide sales and service network, the Kühling&Kühling products can now not only be sold in Europe, but also in the US and Asia. Jonas and Simon Kühling are old hats in this young industry and have been building high-tech printers at their factory in Kiel for five years. The VP 75, which is distributed by us, has had one and a half years of development work. In the future we plan to implement joint development projects tailored to the needs of BigRep customers.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.