Micro-scale 3D printing using innovative polymer resin printers from Boston Micro Fabrication (BMF) is accelerating and improving product development. For example, 3D-printed components have enabled Sutrue, a company in Colchester, England, to bring an automated suturing device for minimally invasive surgery to market.

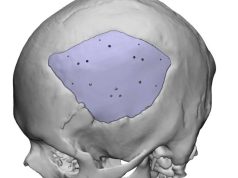

Minimally invasive surgery leads to shorter convalescence times, better healing results and fewer complications. But there are not yet enough instruments to perform these very precise procedures in very confined spaces. Sutrue’s minimally invasive suturing device was developed specifically for keyhole surgery, for laparoscopic and robotic procedures.

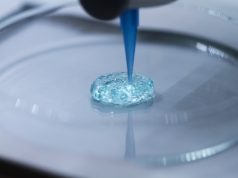

Until now, there was no instrument that could achieve the small diameter of only eight millimeters required for minimally invasive surgery. Alex Berry, founder and chief technical officer of Sutrue, based near Colchester in England, came up with the idea for such an automated suturing device while recovering from a broken ankle in 2008. After years of research and experimentation, Berry’s team had developed a handheld device that automatically feeds a sewing needle with thread through the fabric and back into the device. The needle rotates out of and back into the device on a fixed path while remaining horizontal on the third axis. The tips of the device were prototyped from steel, which took a considerable amount of time and made design changes difficult.

Prototyping a key component

But one of the tip’s most important components needed to be updated to improve the stability of the needle guide. Machining the part would have delayed product testing by several months, added significant cost and left no room for different variations.

3D printing the part to be replaced allowed the team to test different versions and check different tolerances in a short time frame. In addition, 3D printing also allowed the team to consider aesthetics and have the parts printed in two different colors.

“Thanks to the accuracy of BMF’s micro 3D printers, we were able to try three different parts to find the ideal solution. Now our device works as designed, without the cost and time delay of machining,” said Alex Berry, founder and technical director at Sutrue. “The parts printed by BMF match the design and are accurate throughout.”

Advances in minimally invasive surgery

New advances in medical technology will further advance the possibilities of minimally invasive surgery. 3D printing prototypes with the resolution, size and tolerance of precision injection molded parts will enable rapid development of the instruments required for minimally invasive surgery.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.