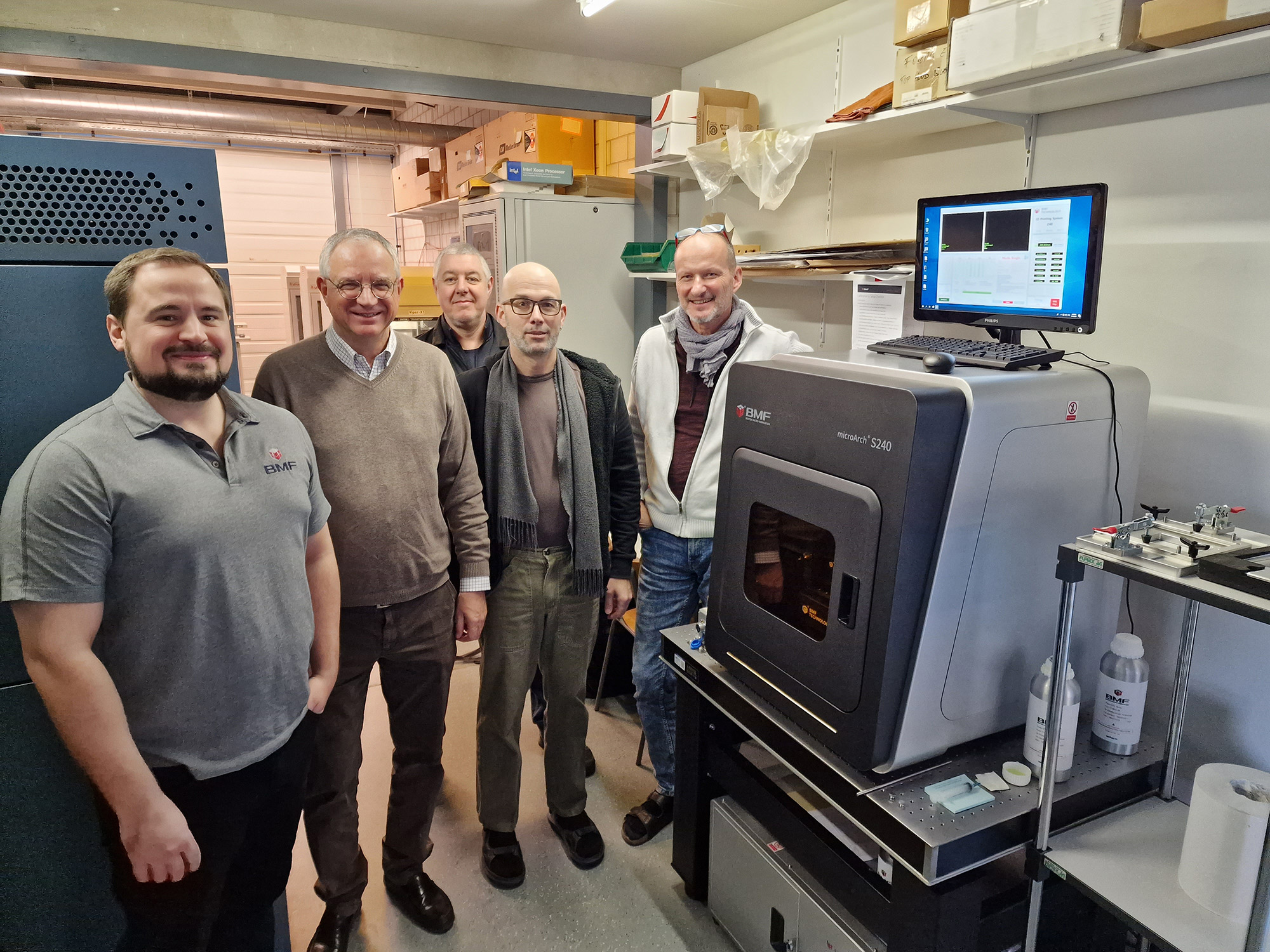

PROFORM AG, an additive manufacturing services company based in Marly, Switzerland, has added a high-precision 3D printer from Boston Micro Fabrication (BMF) to its technology park. The microArch S240 uses patented projection micro stereolithography (PµSL) to print micro parts with unprecedented accuracy. This move is aimed at better meeting the needs of customers in the medical, electronics and other high-precision industries.

“Since then, we have been looking for technologies that would allow us to achieve higher accuracy and surface finish on micro-sized parts,” reports Paul Köhlmeier, owner and CEO of Proform AG.

The microArch S240 has an optical resolution of 10µm and layer thicknesses between 10 and 40 µm. The technology is based on a variant of digital light processing (DLP) developed by BMF, which uses high-precision optics and stepper motors to boost performance.

“The microArch S240 brings the improvements in high accuracy and surface finish that we have been waiting for for so long,” says Paul Köhlmeier. “We can now produce parts with better quality, sharper edges and perfect detail.”

Proform acquired the printer in spring 2023. With a build envelope of 100 x 100 x 75 mm, micro components can be produced from a wide range of resin and ceramic materials. Additional features such as real-time image monitoring and autofocus further optimize the printing process.

“Unlike other manufacturers, BMF allows individual adjustments to the printing parameters,” says Paul Köhlmeier. “This allows us to adjust layer thickness, speed and other factors optimally for the geometry in question.”

The first individual parts and series of 50 to 200 parts have already been successfully produced, confirming the versatility of the new technology.

The microArch S240 enables Proform to better serve its already demanding clientele with more precise and higher quality micro components.

“With BMF’s broad, open range of materials, we achieve numerous different properties, such as biocompatibility, robustness or temperature resistance,” says Paul Köhlmeier.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.