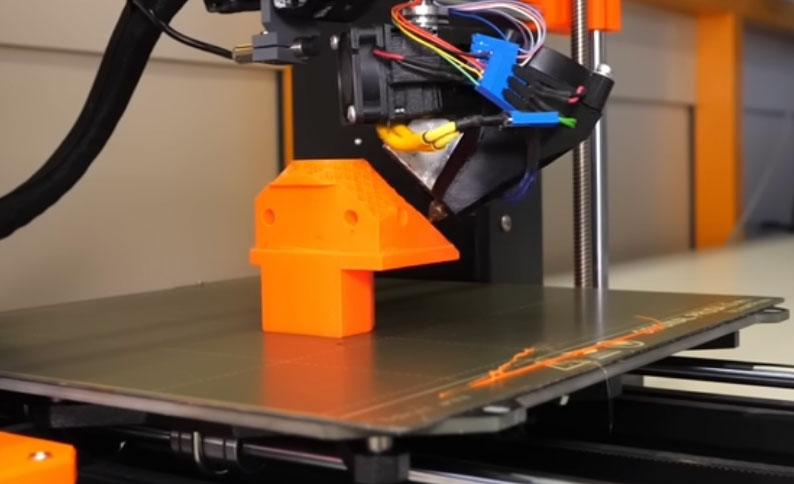

One of the many advantages of 3D printing is the high degree of geometric freedom. Of course, there are some limitations here as well, as the printing of overhangs with a filament-based 3D printer shows. Now, the Zurich University of Applied Sciences in Winterthur, Switzerland, has unveiled a modified Prusa MK3 called RotBot to help with just that.

The RotBot has a DUET control board and a rotatable, 45° tilted tool head. This should also enable the printing of overhangs that a normal filament-based 3D printer cannot print.

Kindly all files were made available online for free, you can find them here (tool head) and here (slicer).

Modifications

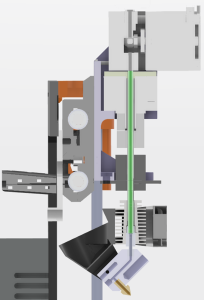

The heart of the RotBot is its rotating print head with the 45° nozzle. On the top is an E3D Hemera direct extruder that feeds the filament through a stepper motor with a hollow shaft to a slip ring that ensures the wires don’t get tangled so the hotend can rotate completely freely and also acts as an additional bearing. Then there’s a slightly modified V6 heat sink and the 45° heating block and nozzle, which is basically the only truly custom, non-printable part in this build.

To increase the clearance, they had to get rid of the bed level sensor, which is now used to reference the rotation axis, and a simple microswitch controls z.

Now, multi-axis non-planar 3D printing technologies have been around for some time, but the unique feature here is the slicing software. Very generalised, you can print overhangs in this +-45° window with an ordinary FDM 3D printer. Conventional tape printers, which have an angled nozzle, tilt this window to 0°-90°. With its rotating print head, the RotBot can reach around a part and enlarge the window to about +-90°, allowing fully overhanging structures on all sides and without supports, creating conical slices – hence the name “conical slicing”. Conical slicing is the method used to generate the g-code for the printer.

Instead of programming a completely new slicer, the engineers tricked the software to generate the paths and then modified this code with a small Python script.

Find out more about the Zurich University of Applied Sciences at zhaw.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.