In the world of 3D printing, there are a variety of settings that can affect the quality and performance of the printed object. A recent video published by the YouTube channel “3D Printer Academy” investigated which settings can achieve the highest strength-to-weight ratio.

The study was conducted in a controlled environment to eliminate possible confounding variables. Different types of walls and infill materials were tested with identical geometry. The aim was to determine the optimum settings to achieve maximum strength with minimum material consumption.

In a first experiment, the number of walls was varied. It was found that the strength increases linearly with the number of walls. However, there were diminishing returns in the strength-to-weight ratio, so that no significant improvement could be recorded above a certain number of walls.

The influence of the degree of filling was then investigated. Here it was found that although a higher filling resulted in stronger objects overall, the strength-to-weight ratio decreased. A combination of the results of both experiments indicated an optimum filling of around 20 percent and three walls in order to achieve a balanced strength-to-weight ratio.

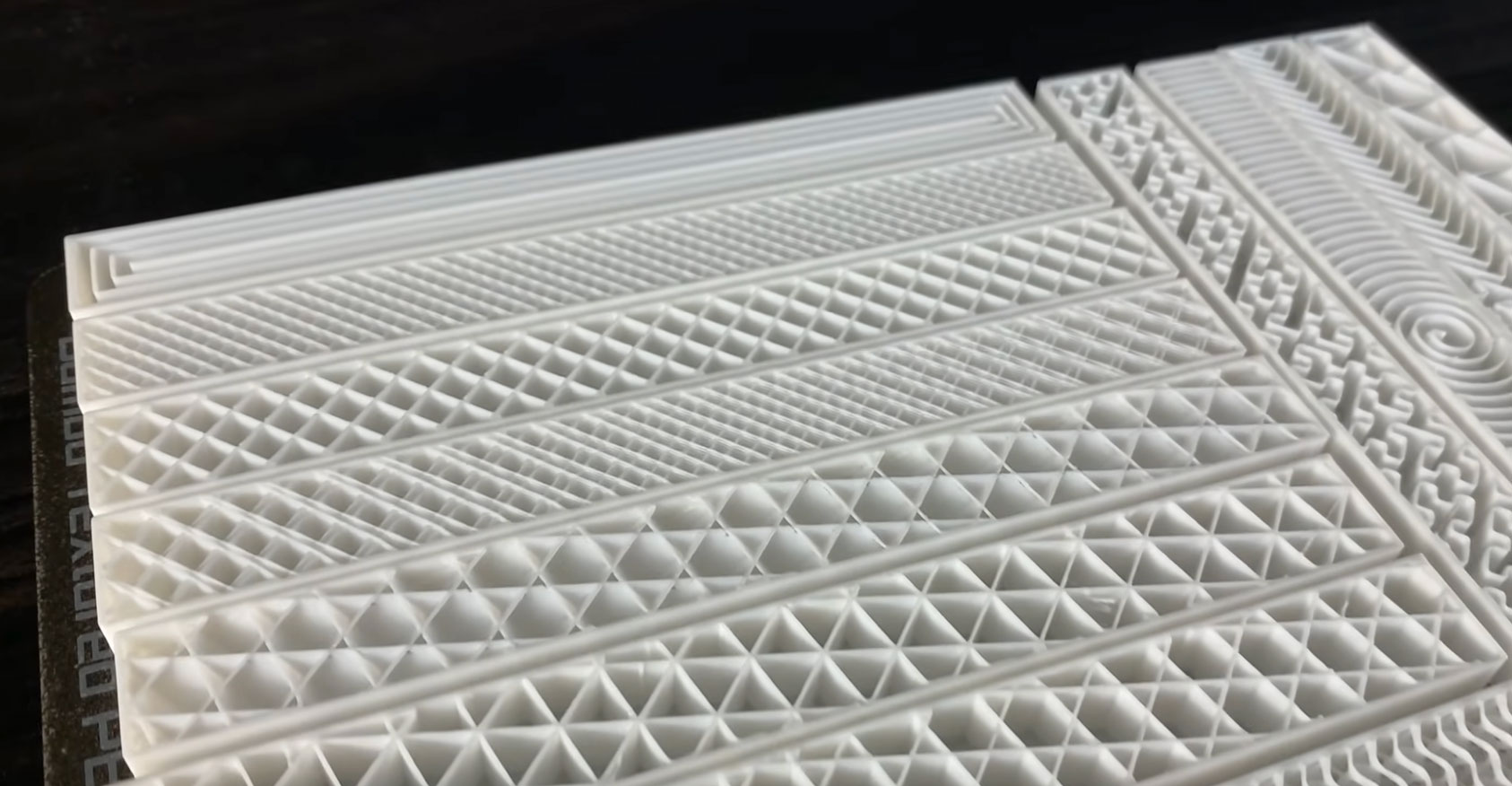

In a further step, different types of filling materials such as grid, cubic or honeycomb were tested. This showed that unusual patterns such as spirals or octagrams were light but less strong. The popular Grid and Cubic fillings performed in the middle of the field with a strength-to-weight ratio of around 3.7 to 3.8. Surprisingly, the Lightning fill pattern, which is known for its low strength, achieved the highest ratio as it is very light and most of the strength comes from the walls. Gyroid and 3D Honeycomb, whose honeycomb-like structure apparently offers high stability, followed in second and third place.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.