On his channel Made with Layers, YouTuber Thomas Sanladerer presents four ways to reassemble multi-part 3D prints later on. This makes it possible to print large parts even with small 3D printers. Printability is often the decisive factor, but stability and handling also play a role.

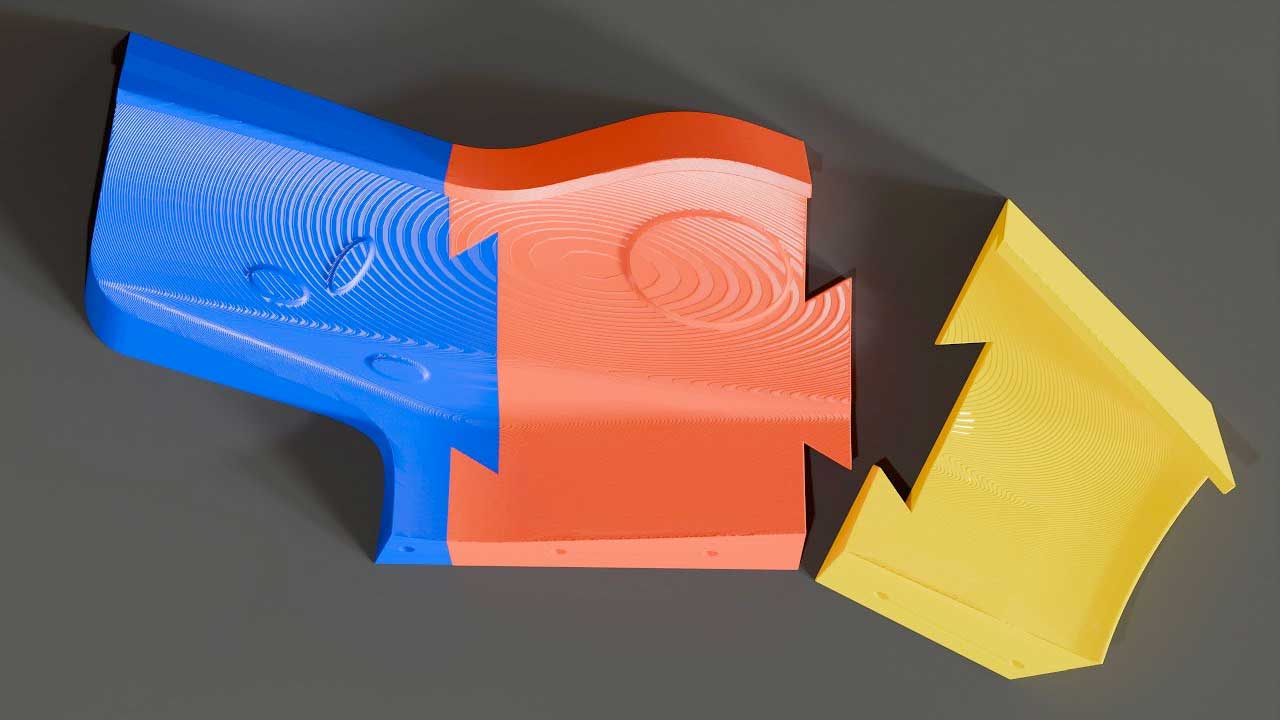

Simple butt joints are easy to produce and assemble with glue, but offer no help in aligning the parts, explains Sanladerer. Form-fit connections such as dowel pins, dovetail joints or threads, which increase precision and strength, are more suitable.

According to Sanladerer, such constructive measures are often not only necessary for dividing large models, but also improve the printing properties in general. With software tools such as Prusa Slicer or Fusion 360, such elements can be easily modeled and integrated into the printed parts.

In his video, the YouTuber explains in detail how the various joining techniques work and how they are created. In his opinion, every 3D printing enthusiast should understand these basics in order to be able to successfully implement more complex multi-part objects.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.