The latest use case by ZMorph shows how a designer utilized 3D printed PVA molds to innovate Metal Fluid casting of highly detailed objects.

Not every object can be cast in a traditional two-part folding mold, mostly because some details and more complex shapes couldn’t be retrieved from it. 3D printed PVA molds offer an alternative that is easier and less expensive than any other DIY and low-cost casting which makes them perfect for freelance designers, artists, and small companies that own a 3D printer.

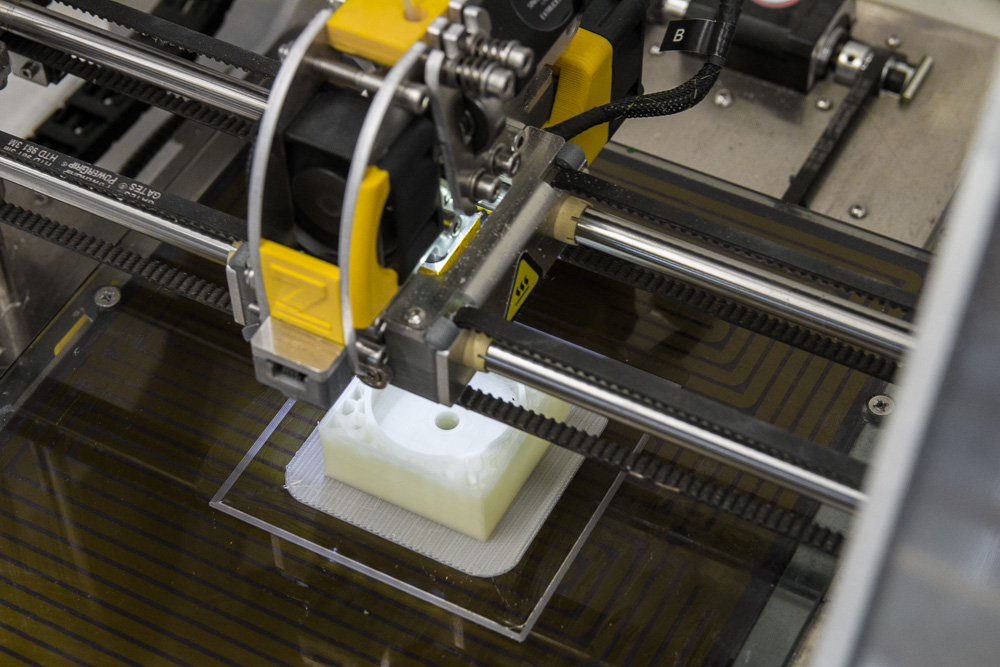

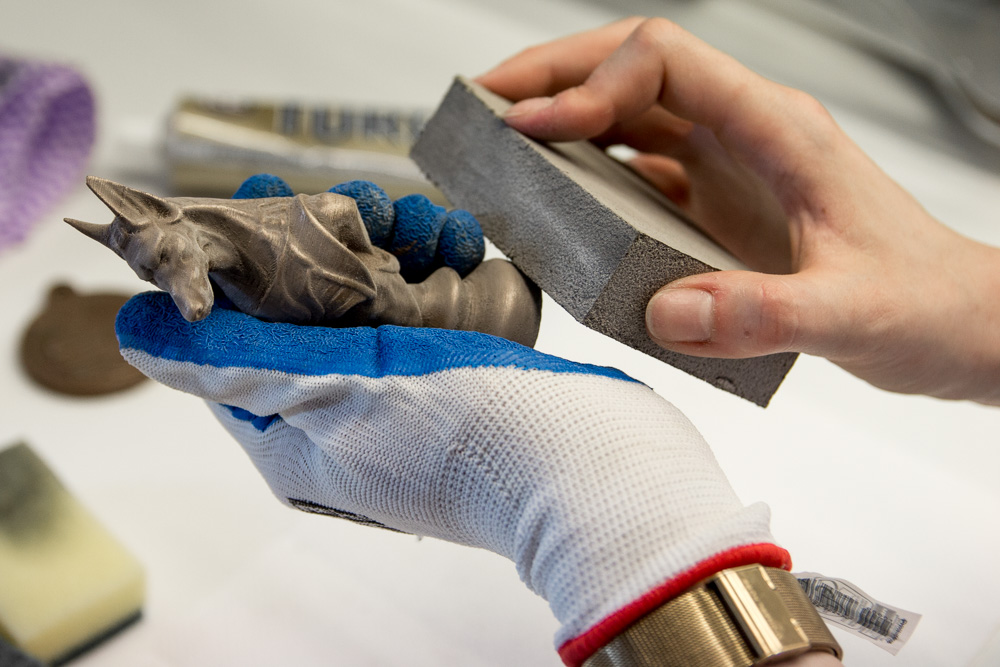

Printed on ZMorph 2.0 SX multitool 3D printer, PVA molds are ready to use straight out of the machine. They’re perfect for Metal Fluid casting because they don’t deform once the material starts to give back heat. After dissolving the PVA, basic post-processing is needed to clean the object and make it look like real metal.

3D printed PVA molds can be successfully applied to create metal figures, prizes, jewelry, antique replicas and high-quality movie props at a fraction of previous costs. They’re much easier and less time-consuming than traditional mold making and metal casting too.

Visit ZMorph’s blog for a step-by-step description of this innovative process.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.