Swedish developer and manufacturer of EBM 3D Printing Systems, Arcam AB, expands its Canada-based powder subsidiary AP&C by adding 3 more atomising reactors.

According to Arcam, the increase of capacity follows on significant growth in 2015 and increased demand for high quality titanium powders.

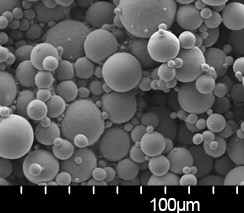

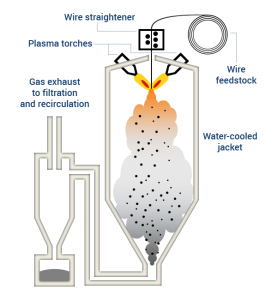

The company uses a proprietary plasma atomisation technology to produce metal powders including titanium alloys, nickel-based alloys and others. AP&C’s plasma technology efficiently converts raw material to powder with excellent key properties such as flowability, density, chemistry and traceability. With the present build-out AP&C will reach a capacity of at least 500 tons per year.

The company uses a proprietary plasma atomisation technology to produce metal powders including titanium alloys, nickel-based alloys and others. AP&C’s plasma technology efficiently converts raw material to powder with excellent key properties such as flowability, density, chemistry and traceability. With the present build-out AP&C will reach a capacity of at least 500 tons per year.

“The need for high end titanium powder is driven by the fast growth and adoption of Additive Manufacturing”, said Arcam CEO Magnus René. “Arcam is determined to serve the industry through cost efficient solutions thus converting traditional manufacturing into Additive Manufacturing. A requisite is to offer highest quality powder for production at competitive cost.”

“The need for high end titanium powder is driven by the fast growth and adoption of Additive Manufacturing”, said Arcam CEO Magnus René. “Arcam is determined to serve the industry through cost efficient solutions thus converting traditional manufacturing into Additive Manufacturing. A requisite is to offer highest quality powder for production at competitive cost.”

According to Alain Dupont, President of AP&C, the company will triple its production capacity in 2016, meeting the superior quality demands of clients in the biomedical and aerospace industries.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.