Following its recent launch, Dimensionics Density reports industry-wide interest in its density determination technology for additive manufacturing (AM).

Philipp Pruesse, Head of Sales at Dimensionics Density, says: “We have been overewhelmed by the response to our commercial launch earlier in early April. Our solution is a revolutionary metrological system designed to deliver rapid and impeccably precise density analysis for various components. AM parts often face the challenge of porosity, which can considerably compromise their mechanical strength and stability. Additionally, porosity poses a threat to the durability of these parts and increases their susceptibility to failure when subjected to stress.”

The effects of porosity extend beyond the mechanical aspects to affect the thermal and electrical properties of AM components, making them more susceptible to high temperatures, corrosive substances and other environmental factors. In addition, the negative effects of porosity also impact the functionality of parts in certain applications. It limits the parts’ ability to absorb liquids, gases or other substances, thus affecting their overall performance.

Dimensionics Density’s density determination solution is designed to revolutionize part density and help improve the mechanical integrity, durability and resistance of AM parts.

“The area in which we are working has a number of alternative but imperfect technologies, all focused on density determination,” Pruesse explains. “However, each has significant drawbacks or limitations when it comes to the requirement to check large numbers of parts, and we have made great efforts to highlight these, and to show how Dimensionics Density provides a superior solution to density determination for series manufacturing, whereas microsections and µCT scans are well suited for parameter development of new materials. So saying, we have commissioned an independent report from the Fraunhofer Institute which benchmarks the different density determination solutions, and this is due for release in a couple of weeks. In addition, we have been spending some time developing an intuitive return on investment (ROI) calculator which will soon be embedded on our new website, and which will give customers a view on just how quickly our technology pays for itself and then contributes to the on-going cost-effectiveness of AM part production.”

Dimensionics Density’s density determination technology is fully automated and production-ready. It is the only viable QC option for analyzing finished steel alloy powder parts, as the material is too dense for CT scans.

“Pruesse concludes, “As we all know, AM stimulates design freedom as it is agnostic to part complexity. As geometric complexity increases, density determination of AM parts becomes more difficult using commonly used density determination technologies. Dimensionics Density’s solutions can easily determine the density of freeform parts and highly complex AM parts and can measure density repeatably to 0.001 g/cm3.”

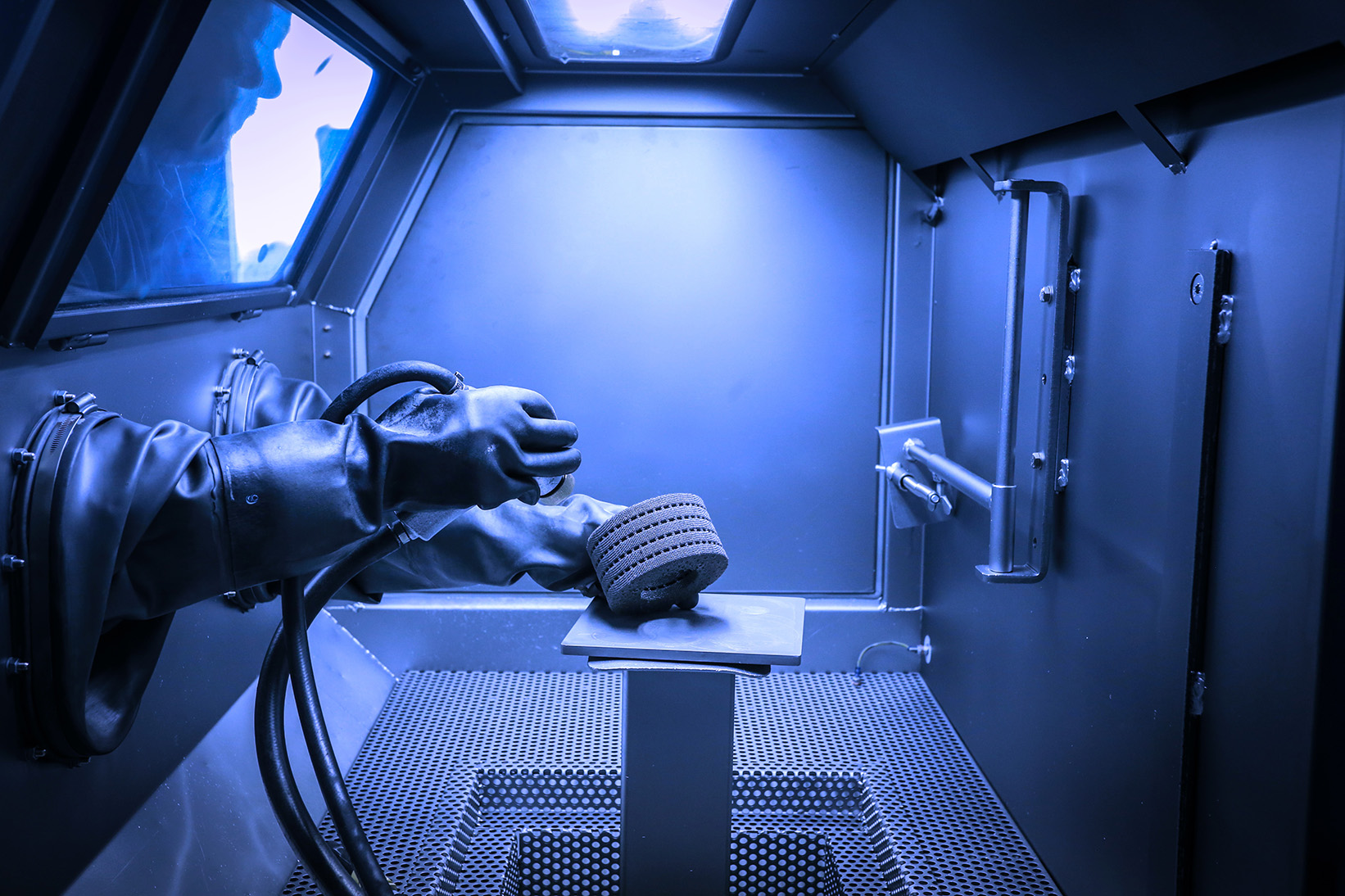

Accuracy is achieved by combining Archimedes’ principle with state-of-the-art automation technology. With a cycle time of less than 2 minutes per component and the ability to inspect up to 18 components simultaneously, the technology contributes to the optimization and efficiency of manufacturing processes. It is non-destructive and enables fast, precise and cost-effective testing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.