Horizon Microtechnologies recently introduced proprietary processes that add material and functionality to microstructures developed for various template materials and shapes.

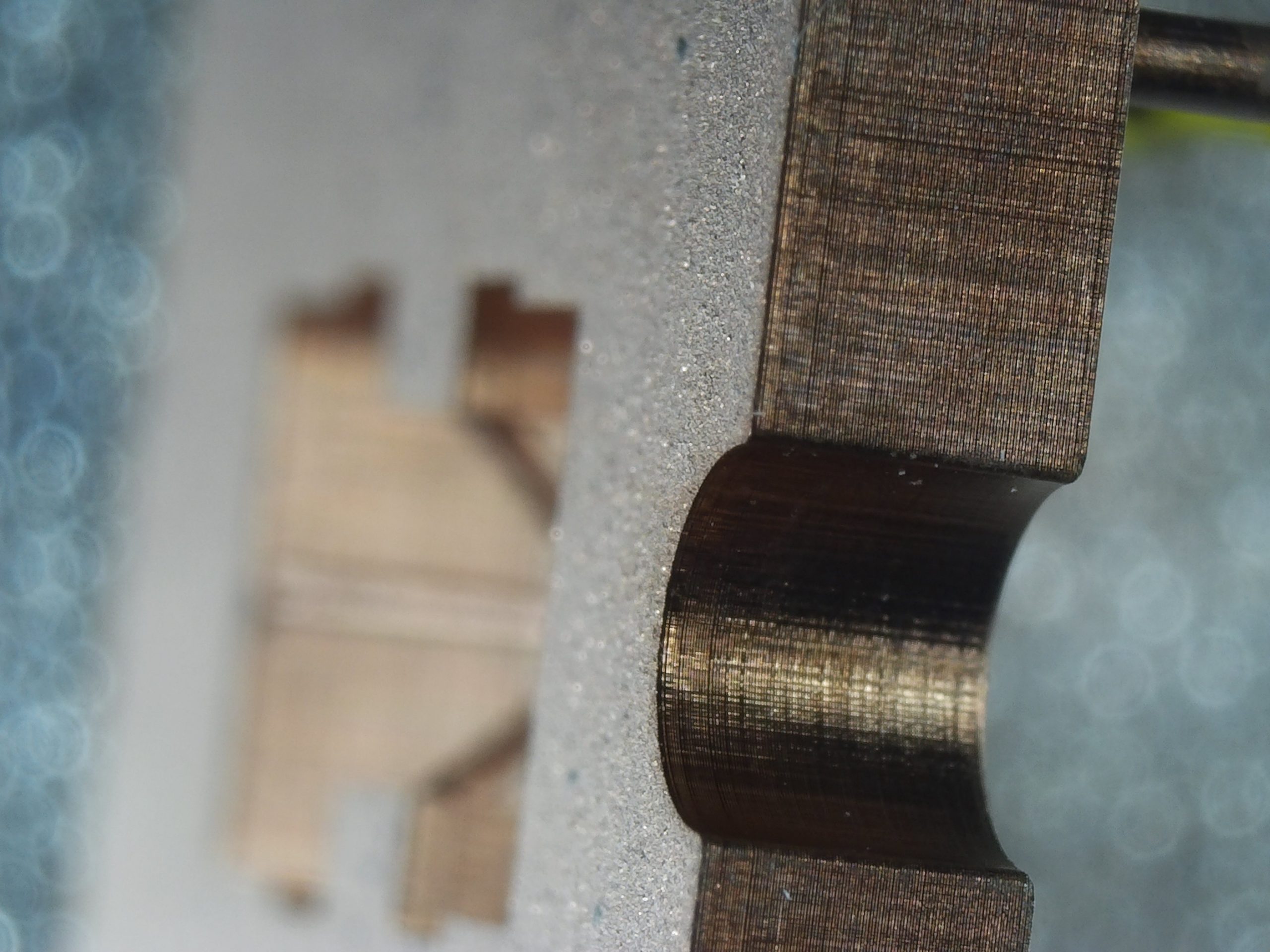

The technologies are particularly suited for micro-AM stencils. Horizon can now apply copper metal coatings to polymer micro-AM and other microstructures, enabling companies for the first time to produce parts with copper functionality and design freedom from micro-AM.

Andreas Frölich, CEO at Horizon says, “Our initial focus is on copper coatings, as this opens up an array of application possibilities for companies wishing to add functionality to micro-AM templates. Copper coatings can offer significant benefits for microfabricated or micro-additive manufactured parts, but there are several challenges and problems associated with current coating solutions that Horizon has addressed to ensure the successful application of the copper. We have carefully optimized the coating process, materials, and deposition parameters, and have overcome these challenges to harness the full potential of copper coating which can now be applied reliably, cost-effectively, and speedily, making it viable for a whole range of applications.”

Frölich continues, “Any technique for deposition of copper coatings requires precise control over process parameters, for example, temperature, pressure or flow rates, to achieve uniform and defect-free coatings. This can be particularly challenging when working with complex part geometries, and again is an area where Horizon has focused its efforts. One of the key reasons why companies seek to use micro-AM parts is because micro-AM opens up design freedom and allows the creation of complex geometries, and so any copper coating technology must be agnostic to complexity in order to be attractive for use with micro-AM parts. Ultimately customers come to Horizon looking for parts.”

Horizon’s coatings are 1 to 2 microns thick, and the process also allows internal channels and undercuts to be coated to some degree. Horizon’s technology is the first to combine the functional advantages of copper with the design flexibility of micro-AM.

Frölich concludes, “With our processes, industry can now access a reliable way to coat three-dimensional micro-AM and other microfabricated templates with copper. Copper coatings can significantly improve the surface properties of micro fabricated parts by adding wear resistance, lubricity, and hardness. The most important use case for the coatings is when highly conductive surfaces are required. Again, of significant importance, (and if designed well) our copper coating can be used not just to coat an entire micro-part, but to selectively coat features on a given template, creating several independent metal features for interconnects, vias, etc. . Selective metallisation has more constraints than uniform metallisation, and so we will happily work with customers to ensure part design is optimised for the process. We look forward to working with interested parties to prove the effectiveness of our copper coating technology, and overcoming preconceptions concerning problems with alternative existing solutions.”

Applications for copper-coated micro-AM and microfabricated stencils include areas requiring high precision, complex geometries and advanced material properties, such as microelectronic devices, miniaturized biomedical devices, drug delivery systems, lab-on-a-chip systems, microreactors and microfluidic sensors, and MEMS actuators and transducers.

Find out more about Horizon Microtechnologies at 3dmicrofabrication.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.