Researchers at MIT CSAIL and the company Inkbit have unveiled a new method for optimizing 3D printing. The method, called “spectral packing,” allows 3D objects to be packed as densely as possible. This could have far-reaching implications, from shipping logistics to mass production in 3D printing.

The researchers, led by Wojciech Matusik, CTO at Inkbit and professor of electrical engineering and computer science at MIT, developed this method to maximize the throughput of 3D printers. It involves packing objects as densely as possible while avoiding interlocking parts with different shapes and sizes.

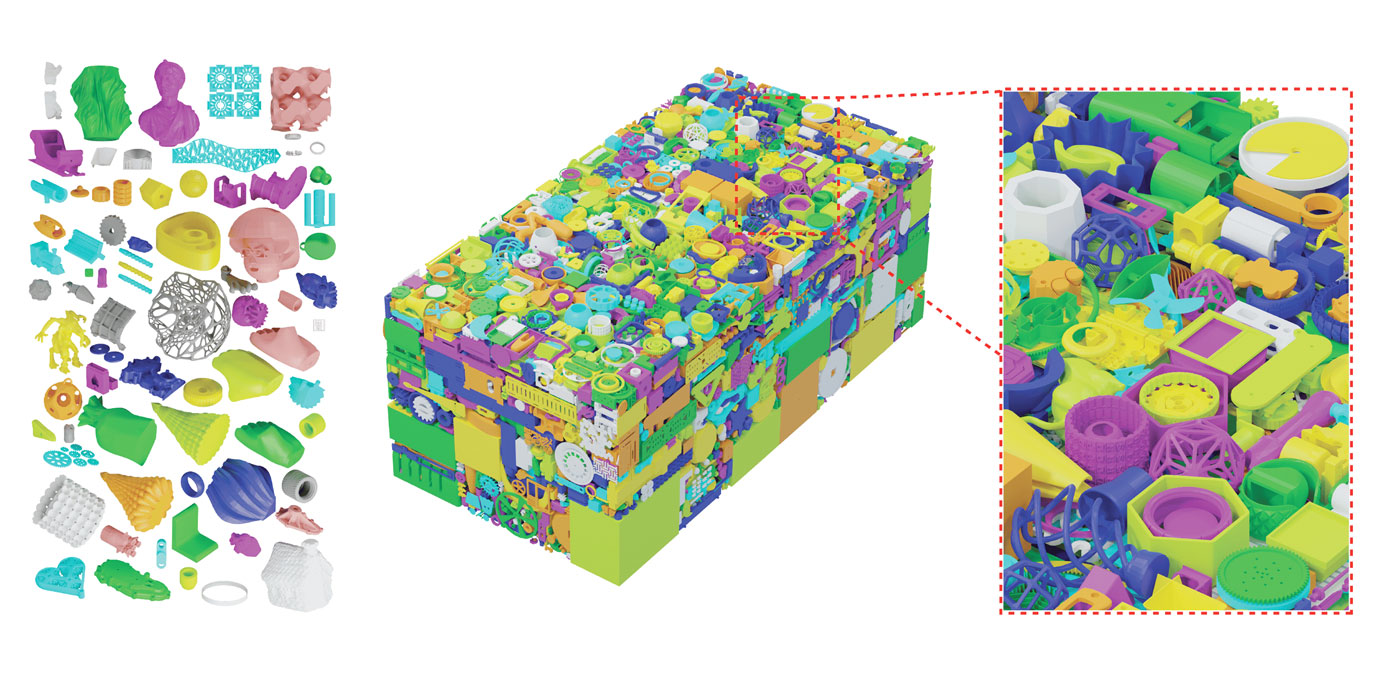

The Spectral Packing method can be compared to a 3D Tetris game. It involves breaking down a box and toys into tiny LEGO-like blocks called voxels. An intelligent algorithm checks that the toy pieces fit without overlapping and aims for efficient use of space. Using a mathematical shortcut called the Fast Fourier Transform, these calculations are performed at high speed.

The researchers demonstrated the efficiency of the new algorithm by placing 670 objects in just 40 seconds, which equates to a packing density of about 36 percent – significantly better than traditional algorithms. This breakthrough has enormous potential, especially in 3D printing, where increased packing density translates directly into reduced costs for manufactured parts. It is also invaluable for shipping and warehousing companies.

Overall, this method shows top performance compared to existing methods in terms of both density and speed. Inkbit has posted more information on its website and the associated scientific paper on a special page.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.