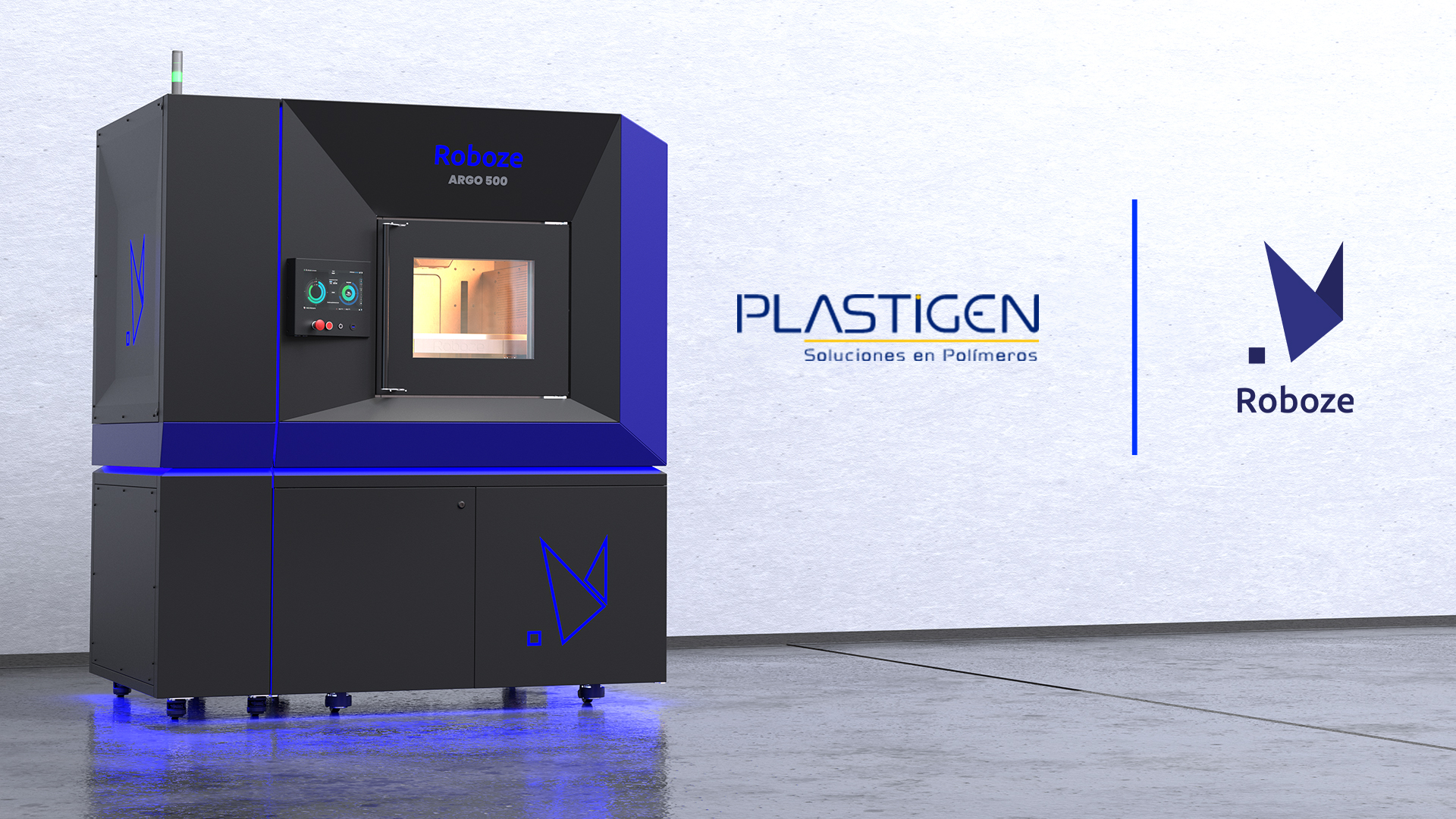

ROBOZE, a leading provider of industrial 3D printing systems, announces the entry of PLASTIGEN, Chile’s prominent supplier of industrial polymers, into the ROBOZE 3D PARTS NETWORK. With this move, Chilean manufacturers and OEMs can now receive high-quality 3D printed parts in real time and on demand.

Chile is increasingly experiencing the impact of Industry 4.0 and the integration of digital technologies into manufacturing processes. With the partnership between PLASTIGEN and ROBOZE, Chilean manufacturers can optimize supply chains, shorten delivery times, and overcome challenges by acquiring high-quality technical parts from remote suppliers.

“ROBOZE’s additive manufacturing has revolutionized the way we produce parts and components, enabling faster production times, reduced costs, and design flexibility. With their expertise in high-performance materials and industrial 3D printing, we want to give Chilean manufacturers access to a reliable source of high-performance technical components resistant to wear, corrosion, and strong mechanical, chemical and thermal exposure, tailored to their specific needs, and on-demand.” says Daniel Irarrazabal, CEO of PLASTIGEN.

The ROBOZE 3D PARTS NETWORK offers customers worldwide access to ROBOZE’s advanced 3D printing solutions and services. With on-demand manufacturing capabilities, the network enables the production of complex parts and prototypes without relying on traditional tooling or expensive molds.

“We are excited to announce the addition of PLASTIGEN to the ROBOZE 3D PARTS partnership network, marking a significant milestone in the localization of advanced manufacturing and empowering the local content in Chile. ROBOZE’s advanced industrial additive manufacturing capabilities, combined with PLASTIGEN’s decades of experience, bring a revolutionary era of innovation to Chile.

Our primary objective is to locally manufacture corrosion; thermal; chemical mechanical resistant industrial parts using composites and polymers that have the potential to replace metal, while simultaneously reducing lead time and costs. By working together, we aim to reshape the traditional concept of warehousing, and transforming it into digital where parts can be efficiently produced on-demand, with a greater focus on sustainability. “says Arash Shadravan, ROBOZE Global Business Development Director. “Together, we embrace the transformative power of additive manufacturing, forging a future where technology and sustainability converge for the benefit of both industry and planet.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.