A team at West Virginia University is investigating how 3D printing behaves in zero gravity in space. According to a publication in ACS Applied Materials & Interfaces, the research is intended to support long-term missions and the colonization of the moon and Mars.

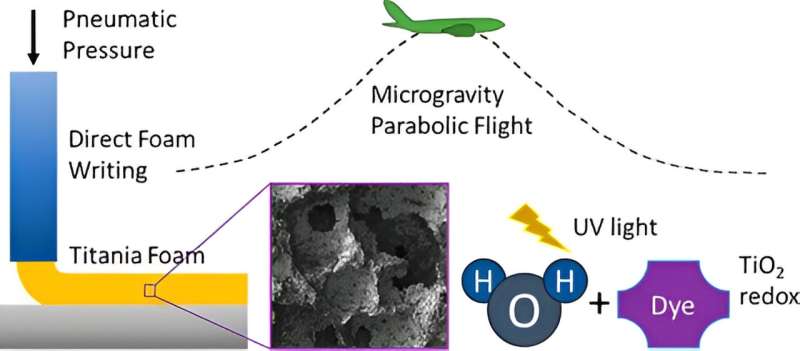

According to the researchers, the properties of the printed material change in zero gravity. Porous titanium dioxide, which is suitable for UV protection and water purification, was tested. The printing results in space differed from tests on Earth.

According to lead PhD student Jacob Cordonier, 3D printing in space is essential because materials cannot be carried in unlimited quantities. Instead, equipment and spare parts have to be manufactured on site. According to the researchers, titanium dioxide could be extracted on the moon and used for protection and equipment.

In tests, the titanium dioxide material showed a high absorption of UV radiation and was suitable for water purification. University students were involved in the research and constructed a compact 3D printer specifically for space experiments.

According to the researchers, the technology could help astronauts to use existing resources efficiently without the need for supplies from Earth. The results provide important insights into how 3D printing can enable extraterrestrial missions.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.