A new study has looked at 3D printing of the nickel-based superalloy steel Inconel 625. Scientists at the National Institute of Technology Karnataka in India investigated the influence of different deposition strategies and subsequent heat treatment on the microstructure and mechanical properties.

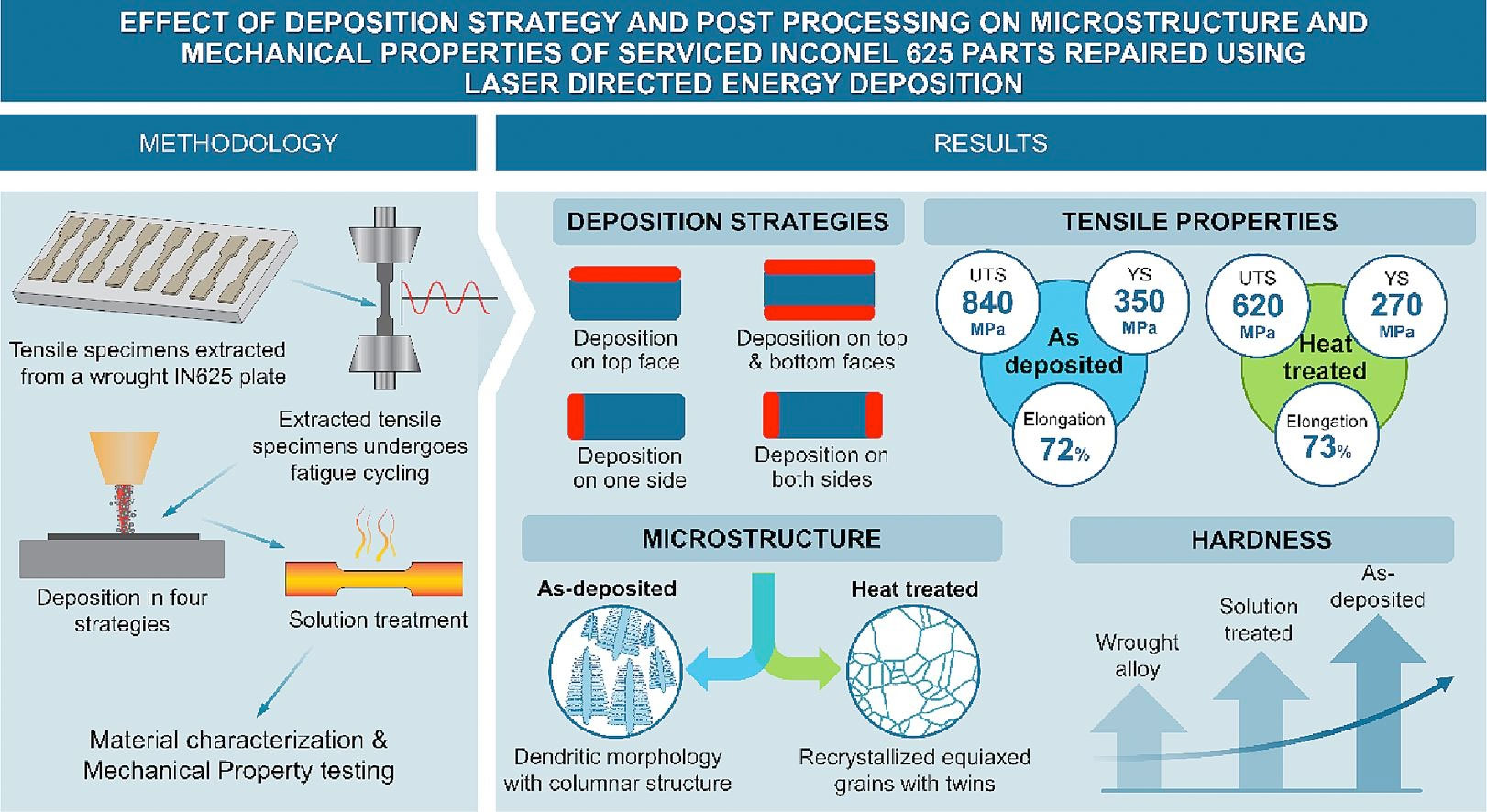

Using the 3D printing process Laser Directed Energy Deposition, test specimens were deposited on pre-stressed Inconel 625. Four deposition strategies were used: deposition on one side, on both sides, on top and top only, and on the bottom. Part of the specimens were subjected to solution annealing at 1200 degrees Celsius.

The study showed dense deposition averaging 1.02 millimeters in thickness for all strategies. A dendritic microstructure was found in the untreated specimens, which gave way to a recrystallized grain with twinning after heat treatment. Mechanical parameters such as tensile strength and hardness dropped after annealing, while elongation at break increased.

According to the researchers, 3D printing is well suited for repairing Inconel components. Suitable process parameters and adapted heat treatment can achieve properties that are close to the starting material. The study shows that the technology is suitable for reworking worn components made of high-cost superalloys, they said.

The full paper, titled “Effect of deposition strategy and post processing on microstructure and mechanical properties of serviced Inconel 625 parts repaired using laser directed energy deposition” can be viewed here. Authors of the paper are Jitender K. Chaurasia, A N Jinoop, C.P. Paul, K.S. Bindra, Vamsi Krishna Balla and Srikanth Bontha.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.