3D printing material developer and manufacturer Taulman3D adds yet another material to its portfolio of high quality filaments. Guildl!ine is ISO 10993 certified and has been created specifically for medical and clinical applications.

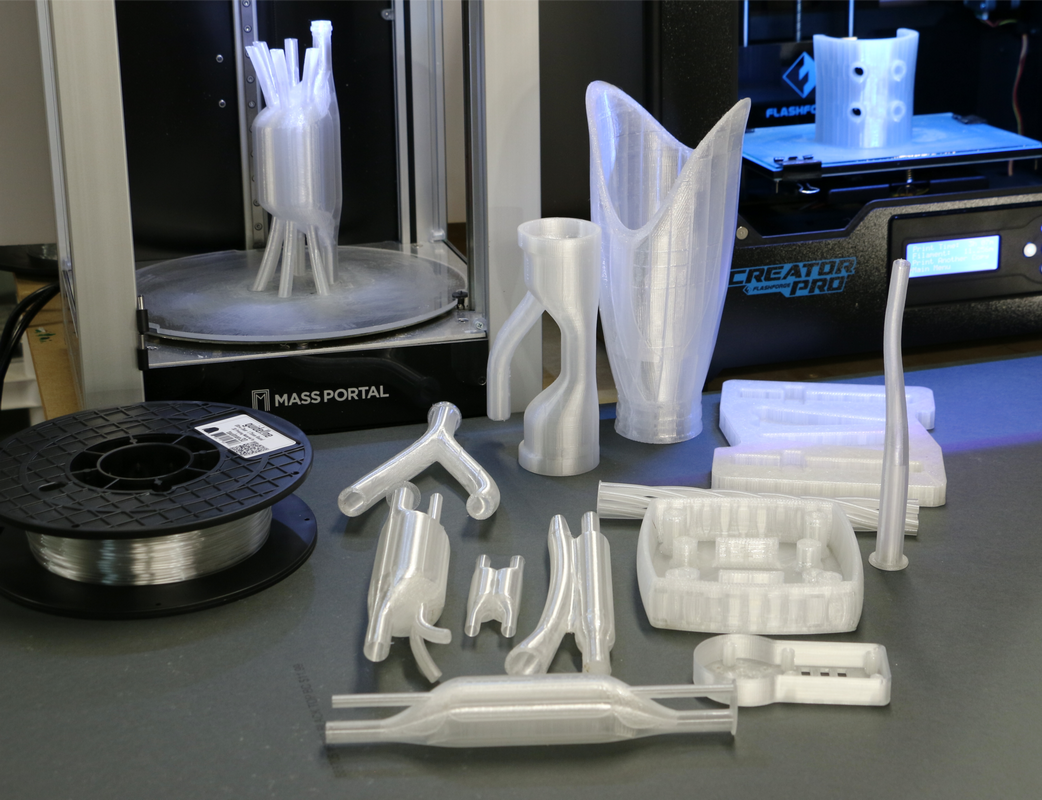

The clear high-strength filament is based on PETG thermoplastic polymer and features excellent high temperature printing capabilities. This allows for printing even small details of parts without distortion as well as watertight, hollow tubes. Having already passed specific FDA testing, guidel!ne is ideal for companies to get 3D printed medical devices certified. The raw material is extruded in a manner that keeps contaminates out of the material during the cooling process. Additionally, pH and ORP levels are monitored and adjusted in order to maintain acceptable levels.

guidel!ne has a tensile strength higher than taulman’s proprietary TECH-g (6,850 PSI). Its heat distortion temperature is 70°c and softening temperature 100°C. The ideal printing temperature is 250°C.

Taulman’s new filament is available in 1 pound spools in both 2.85 and 1.75 mm diameter.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.