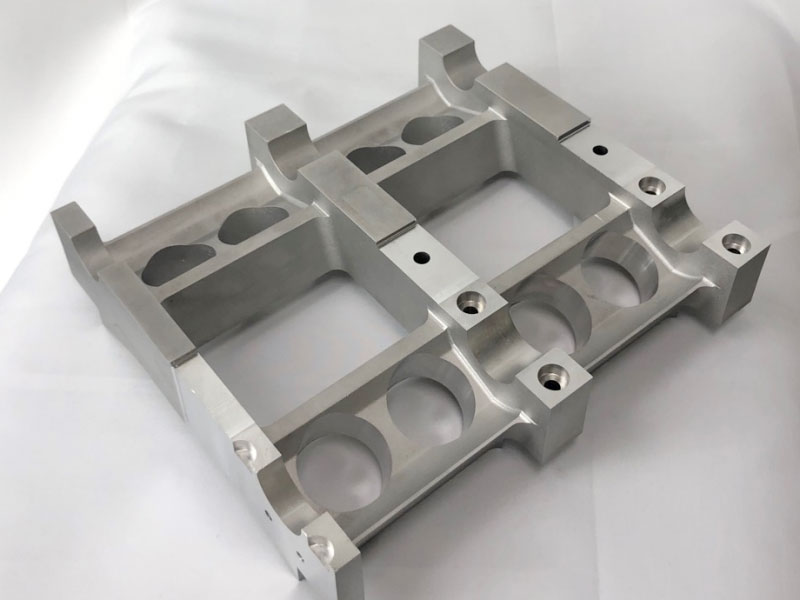

Engineered materials specialist Uniformity Labs (Uniformity) announces the availability of its UniFuse AlSi10Mg aluminum powder and optimized parameters for 50um and 90um laser powder bed fusion (L-PBF) printing. This follows the previously announced release of UniFuse AlSi10Mg and optimized parameters for 30um layer thickness printing. The UniFuse AlSi10Mg powder and processing parameters for each layer thickness are optimized for the best material properties and repeatability while maintaining the highest print throughput on all L-PBF platforms.

Uniformity Labs has now designed High-Performance Scanning parameters for printing UniFuse AlSi10Mg at 50um and 90um layer thickness in platforms with lasers exhibiting maximum power between 400W and 700W. Uniformity materials and High-Performance Scanning deliver superior properties at an approximately 75% increased build rate compared to competitors’ same layer thickness scan strategies. This throughput improvement is typical for UniFuse AlSi10Mg builds.

Higher bed and tap densities with particle size distributions optimized for uniform, repeatable printing at the highest throughput enables Uniformity powders to deliver improved mechanical properties and consistent performance across the build bed, even printing at thicker layers with high laser powers.

“With UniFuse AlSi10Mg we’re able to deliver best-in-class mechanical properties, surface finish, printing yield, and part reliability with substantially increased throughput printing at 50um and 90um layer thickness, and when using higher power lasers,” said Uniformity founder and CEO Adam Hopkins. “This is significant for advancing AM as a viable pillar for industrial manufacturing and shows that our technology and process deliver on the promise of no compromise additive manufacturing.”

Uniformity Labs is addressing the industry challenge of achieving serial production in AM with the development and production of its highly advanced ultra-low porosity metal powder feedstock. Currently in production under the product brands UniFuse (for L-PBF) and UniJet (for binder jetting), and with its High-Performance Scanning strategies, Uniformity Labs has dramatically improved the ability to produce high-quality parts repeatedly and at scale – allowing additive manufacturing to become an increasingly better-established serial production tool.

This announcement follows the recent availability of a range of steel, aluminum, and titanium powders under the brand UniFuse for L-PBF and UniJet for binder jetting, with many others nearing availability. Datasheets and use cases can be found here.

Find out more about Uniformity Labs at

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.