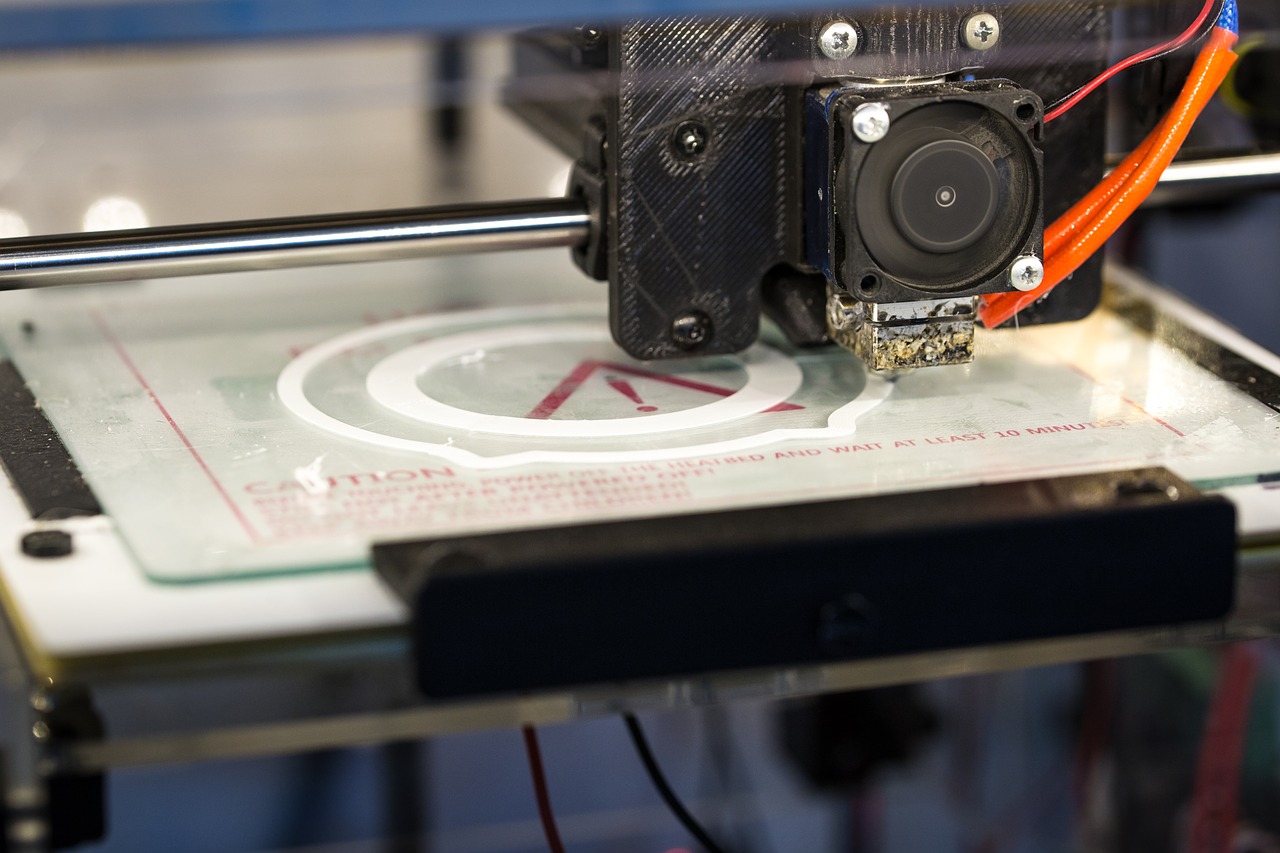

When most people think of 3D printing, they think of FFF or FDM style printers that extrude plastic. However, many may not be aware of how far-reaching the applications of 3D printing and additive manufacturing are, with metal printing, construction printing and bioprinting showing off the range this one label of technology can carry.

The truth is that 3D printing is not any one single technology but rather a catchall term for a whole host of additive manufacturing methods. The diverse range of functions this one term carries can be staggering, so we’ve decided to compile 10 of the most out-there, niche purposes that fall into the category of 3D printing.

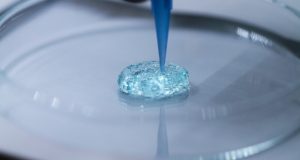

1. Artificial Meats

The picture above may look like a regular, juicy steak, it’s actually a composite artificial meat composed of plant-based components. Israel-based start-up Jet Eat has made its name in producing steak that tastes as close to the real thing as possible. The company isn’t just battling the conception that artificial meats can’t be as flavorful as the real thing. They’re also looking to prove that there are sustainable environmental ways to produce food alternatives that can curb the massive amount of carbon emissions from the meat industry.

The company has ambitious plans in uprooting the way we eat. While they are still a start-up they’ve gained quite a bit of notoriety and won some grants and awards for their technology. Perhaps artificial meats may not be as far as one would think.

2. Self-Replicating 3D printers (They want to use these to build lunar bases)

While still very much a concept, Carleton University in Ottawa are working on a 3D printer that can repair and reproduce itself. Moreover, it is being designed to use the materials around itself to recreate other 3D printers and units. While the printer is a novel idea, it is still running into some roadblocks till the concept is complete. Firstly, it can easily convert plastics and soil, but is not versatile enough to work with metals (which are crucial to its mechanical functions).

Still, the concept of self-replicating printers is a fascinating one. These machines would be a massive aid in construction, particularly in space, where autonomous machines are a necessity.

3. Recycled Parts Using Trash

One of the major concerns with 3D printing is the overuse of plastic that it may reintroduce into the economy. However, where one could see a possible problem, others see an opportunity for technological solutions. Certain initiatives have shown this to be a novel, practical solution to waste. One of the most interesting use cases comes from the US military. Capt. Anthony Molnar from the U.S. Marines generated 3D printing filament from recycled polyethylene terephthalate (PET) deriving it from bottles and plastics without any chemical modifications or additives.

Not only did they take ordinary bottles and produce a usable filament, they were also able to compress it into a far stronger plastic. The process could relieve the very large amount of plastic waste that exists all over the world. Ocean cleanup companies, recycling plants and various other socially conscious organizations are applying these sorts of principles and their wider adoption may be a massive boon to ecological protection.

4. On-demand Customizable Fashion

One of the great, unique things that 3D printing brings in is on-demand, customizable goods. Nowhere is this more promising than the world of fashion, where 3D knitting and printing technologies are taking clothing to the next level while empowering the buyer to express themselves using digital models. From world-renowned designer Danit Peleg to Adidas and Nike, 3D models that user can precisely fit to their own specifications.

This model of clothing and footwear design works can require visiting a dedicated facility but could just as easily be accessible through a website and home delivery service. Convenient and customizable, they offer a potentially disruptive model of fashion development.

5. Make-up Printers

Much like how 3D printing is bringing more to fashion, its also taking a dive at the world of make-up. The Mink 3D printer is an odd little device that instantly transforms images into wearable makeup, using a tri-color cartridge that opens up numerous combinations of colors.

Using the Internet or its own app, the printer can take an image and make a make-up mask out of it, which can be applied to body. It can quickly create designs that would be laborious to do manually and may find use in fashion, film make-up or even cosplay. It brings a level of ease to the process that remains unrivalled.

6. Coral Reef Reconstruction

Coral reefs are a major part of the marine environment and house many different fish and microorganisms, which are reliant on their continued existence. The decline in their habitat has been a prominent ecological disaster that needs addressing. Luckily, 3D Printing isn’t just for manufacturing, but also brings with it new ways of fixing a lot of modern problems. From Monaco to Australia, marine biologists and researchers have been reconstructing these habitats using additive technologies.

While this solution is merely an example of fixing the symptoms as opposed to dealing with the causes (i.e. ocean pollution and climate change), the process does provide temporary relief to many marine species. It may not be the end-all be-all cure, but it is necessary in curbing this problem. It also showcases the wide-ranging applications of additive manufacturing.

7. Printing Moondust

Multiple projects have actually had this idea in recent years. From the Laser Zentrum Hannover e.V. (LZH) and the Institute of Space Systems (IRAS) to Northwestern University, using lunar regolith has been somewhat of pet project for the world of space exploration-based 3D printing. While the systems may differ, with some using SLM and others applying inks and standard printing, the object remains the same: using extra-terrestrial soil to produce structures for lunar exploration.

Bringing 3D printing to space in this way is immensely useful. It decreases the amount of resources one needs to carry with them. Not only does it decrease material weight (which massively curbs the use of rocket fuel), it also means there is an easier way to build tool and possibly even houses in space. Such devices are not just helpful, they may be crucial to the future of space travel.

8. 3D Printing Vinyl Records

While vinyls are a niche entertainment product, they’re still quite expensive. One of the reasons for this is that the technology has not improved since its inception. Vinyls are where they left off when they were replaced by cassettes and CDs. However, one of the cheaper alternatives comes in the form of (you guessed it) 3D printing.

While vinyl printing is not a common thing, it has been demonstrated to work (albeit, with less than desirable quality). However, with some tweaking to the method and materials, this could be a worthwhile means of reproducing these musical products. It could allow for music labels converting music to stl files and distributing digital files that could be converted to analogue products.

9. 3D Printing With Your Phone

While the ONO concept didn’t really pan out, it’s still worth mentioning because of what an interesting and novel idea it was. Certain companies like the Kickstarter ONO planned to turn your standard smartphone into a 3D printer using an app and a box, which will use the screen of the phone to mimic the functions of SLA or DLP. The company made the method sound very simple: users would place their phone in a box, activated an app and placed resins into a screen. The box would activate the lights from your phone, moving a platform to create the 3rd dimension and process the light-curable resin.

Whatever went wrong, we don’t know. The concept had many backers but appears to have stalled. Still, it’s an interesting prospect that we hope gets picked up once again and gains some steam.

10. Unbreakable Guitars

Engineering firm Sandvik recently 3D printed a titanium guitar that they deemed unbreakable. The customized guitar was developed using powders and laser deposition methods, featuring a titanium body and steel neck. One of the things that set it apart was that the body was not made in many separate components, but rather featured as few as possible with mostly a single-piece frame.

The guitar was indeed unbreakable, continuing to function and play properly after being beaten, bashed, tossed and flung across the stage by veteran guitarist Yngwie Malmsteen. While expensive, the guitar offers a glimpse into new design opportunities with solid structures and new architectures.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.