3D-printed orthoses made from Windform GT material will be presented at the upcoming SuperPower Design trade fair. The event will take place from March 24 to August 25, 2024 at the prestigious Center for Innovation and Design (CID) in Grand-Hornu, Belgium.

Windform GT, a fiberglass-reinforced composite material specially developed for Selective Laser Sintering (SLS), is characterized by excellent thermal and mechanical properties. With a density of 1.19 g/cm³, a heat deflection temperature of 169.4°C under load, a tensile strength of 56.21 MPa and an elongation at break of 14.82%, Windform GT offers unprecedented durability and flexibility.

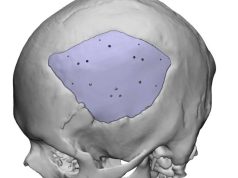

The special feature of these orthoses lies in the customized production through generative design, made possible by 3D printing technology. They are specially tailored to the individual needs of all patients and offer improved physical performance. Special features include adaptability to the body, correct movement control, water resistance, an optimal strength-to-weight ratio and flexibility.

Franco Cevolini, CEO and Technical Director of CRP Technology, expresses pride in their inclusion, stating, “We are honored that the 3D printed orthoses in Windform GT by MHOX have been chosen to be showcased at the SuperPower Design exhibition. These orthoses exemplify how cutting-edge design, industrial technology, and advanced materials can empower individuals, transcending physical limitations and enhancing quality of life.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.