The company AIM3D has investigated the suitability of ULTEM plastic pellets for 3D printing. The focus was on AIM3D’s pellet 3D printers compared to conventional filament-based FFF printers. The goal was to take advantage of the significantly lower material costs of plastic pellets.

Until now, filament 3D printers have dominated printing of the high-performance plastic ULTEM. Instead, AIM3D relies on its proprietary CEM (composite extrusion modeling) process, which uses standard plastic pellets.

According to AIM3D, the use of ULTEM pellets promises a material cost that is about seven times lower than expensive filament material. In addition, pellet printers such as AIM3D’s ExAM 510 enable significantly higher build rates.

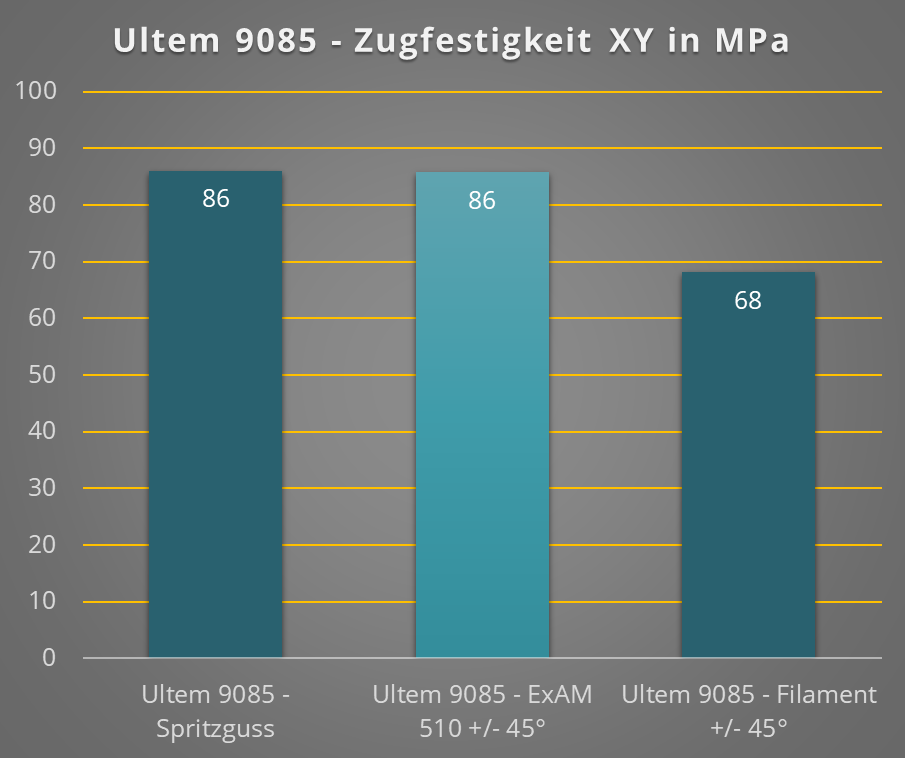

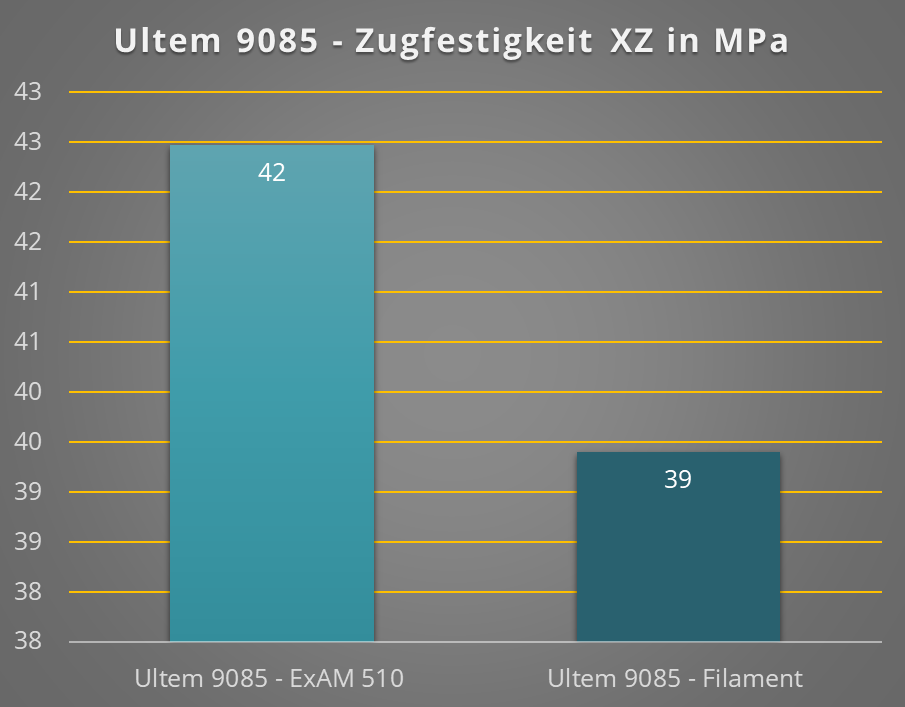

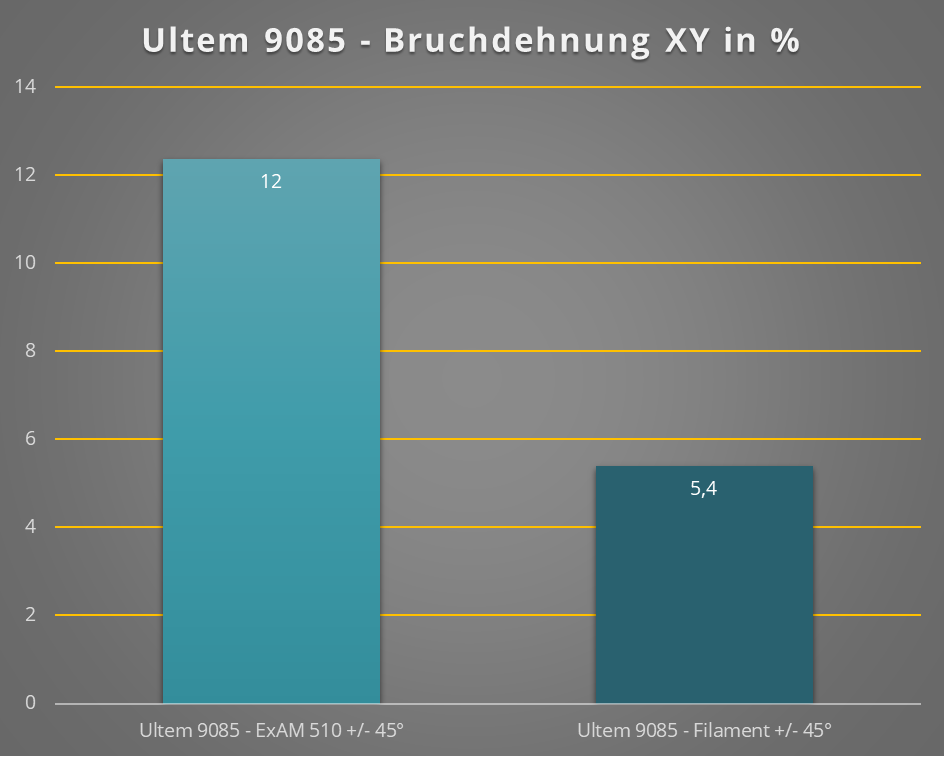

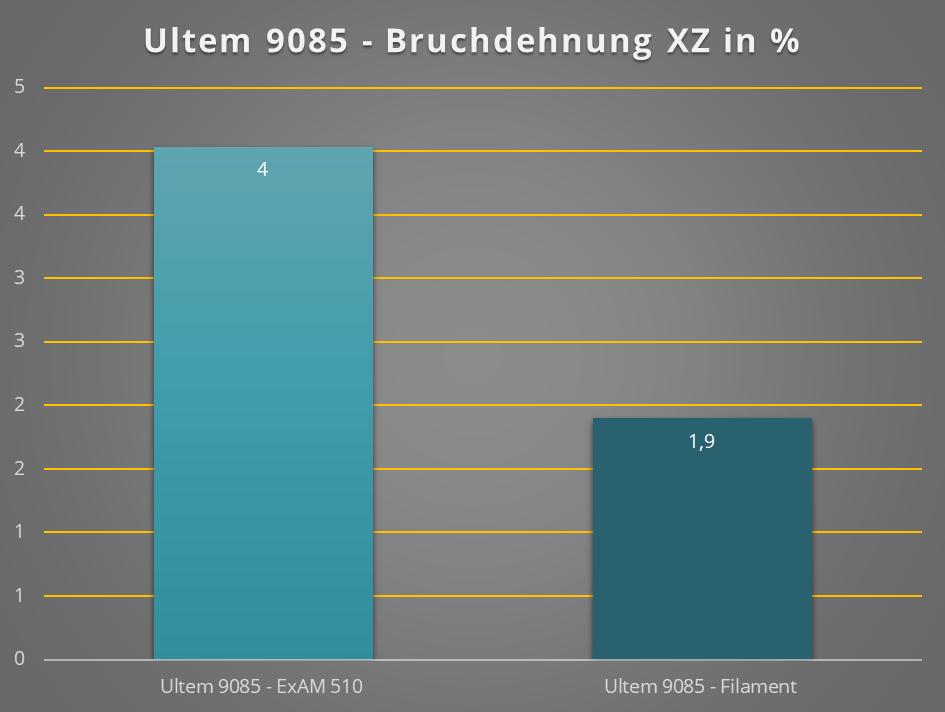

In tests with Sabic’s ULTEM material 9085 Resin, pellet technology was able to achieve tensile strengths comparable to injection molding. In some cases, the values were significantly higher than those of filament printers. Reproducibility and elongation at break were also better with pellet printing.

According to AIM3D, the pellet-based CEM process opens up new application areas for ULTEM, which is used in aerospace, for example. Cost-intensive application scenarios could become more attractive.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.