US-based Carbon has introduced EPX 150, a new high-temperature resin material for 3D printing. EPX 150 adds versatile design and manufacturing capabilities to the material options for Carbon’s Idea-to-Production platform.

Carbon says the material creates new potential applications that require high temperature and chemical resistance. Examples include electrical connectors, spray nozzles and autoclavable medical devices. EPX 150 is available immediately in Europe and North America.

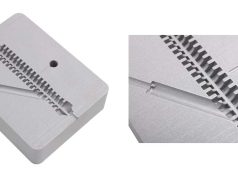

Compared to other carbon materials, EPX 150 features improved temperature and chemical resistance as well as high toughness and ease of use. It is especially suited for high-speed printing of complex parts with fine structures and tight tolerances.

According to Carbon Manager Jason Rolland, EPX 150 combined with carbon technology enables a production-ready additive process that achieves the capabilities of high-performance thermoplastics. This allows prototyping and volume production to occur on one platform, reducing development time and costs.

EPX 150’s advantages include high thermal stability, exceptional chemical resistance at temperatures up to 125°C, suitability for over 250 autoclave sterilization cycles and low dielectric constant. EPX 150 is also designed for efficient printing of filigree parts with longer service life.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.