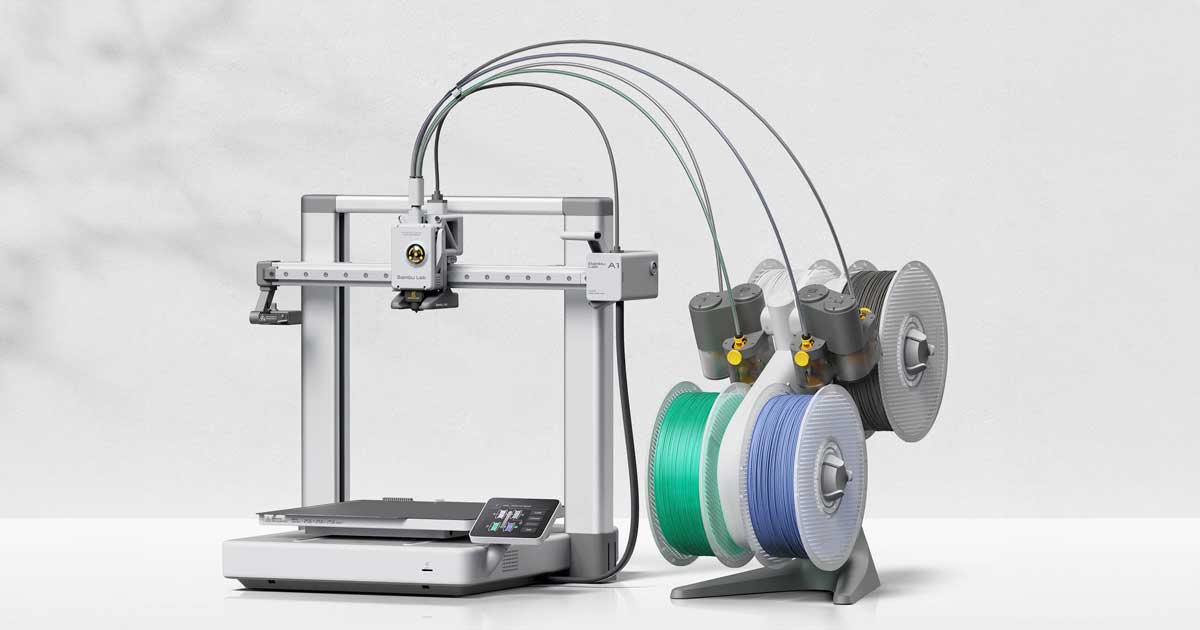

The Bambu Lab A1 Combo is a new 3D printer with a 4-fold material changer that should appeal to beginners in particular. With a print volume of 256 x 256 x 256 mm, it offers a buildable build space and some unique features that set it apart from other printers.

The Bambu Lab A1 Combo 3D printer offers an impressive build volume of 256x256x256 mm³, supported by a high-quality, all-metal, stainless steel hot-end nozzle. The nozzle comes standard with a diameter of 0.4 mm, with options for 0.2 mm, 0.6 mm and 0.8 mm also available. The maximum temperature of the hot end reaches up to 300 °C, while the build plate can be heated up to 100 °C. The supplied Bambu texture PEI plate ensures excellent adhesion, and a high-temperature plate with a smooth PEI surface and a cool plate are also available.

In terms of speed and precision, the printer offers a maximum toolhead movement speed of 500 mm/s and an acceleration of up to 10 m/s². It is compatible with a wide range of filaments, including PLA, PETG, TPU and PVA as ideal materials. However, ABS, ASA, PC, PA, PET and carbon or glass fiber reinforced polymers are not recommended for use.

Features also include various sensors to enhance the printing experience, including a low frame rate chamber monitoring camera (up to 1080P) with support for time-lapse recording, an end of filament sensor, filament odometry, power failure recovery and a filament entanglement sensor.

The physical dimensions of the A1 are 385x410x430 mm³, with a net weight of 8.3 kg and a gross weight of 11.7 kg for the package. The A1 Combo package, which also includes the AMS Lite, has a package size of 546x536x420 mm³ and a gross weight of 14.3 kg.

The Bambu Lab A1 Combo shares many features with the larger X1 and P1 models, such as the use of the same smartphone app and the same slicer. Of particular interest is the in-house AMS (Automatic Material Switching) Light System, a more open version of the automatic material switching system of the X1 and P1. Although the functionality is almost identical, the systems are not compatible due to different connectors.

Technical specifications

| Item | A1 Specification | |

| Body | Build Volume(W*D*H) | 256*256*256 mm³ |

| Toolhead | Hot End | All-Metal |

| Nozzle | Stainless Steel | |

| Max Hot End Temperature | 300 °C | |

| Nozzle Diameter | 0.4 mm (Included) 0.2 mm, 0.6 mm, 0.8 mm | |

| Heatbed | Build Plate | Bambu Textured PEI Plate (Included) Bambu High Temperature Plate (Smooth PEI) Bambu Cool Plate |

| Max Build Plate Temperature | 100°C | |

| Speed | Max Speed of Tool Head | 500mm/s |

| Max Acceleration of Tool Head | 10m/s² | |

| Supported Filament | PLA, PETG, TPU, PVA | Ideal |

| ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced Polymer | Not Recommended | |

| Sensors | Chamber Monitoring Camera | Low Frame Rate Camera (Up to 1080P) Timelapse Supported |

| Filament Run Out Sensor | Yes | |

| Filament Odometry | Yes | |

| Power Loss Recover | Yes | |

| Filament Tangle Sensor | Yes | |

| Physical Dimensions | A1 : 465*410*430 mm³ , Package size : 552*532*320 mm³ , Net weight 8.3 kg , Gross weight 11.7 kg A1 Combo : Package size 546*536*420 mm³ , Gross weight (AMS lite included) 14.3 kg | |

Our test

The printer arrives compact and well protected and can be set up easily and without complications thanks to the enclosed instructions. In addition to the usual tools, instructions and mini SD card, the scope of delivery mainly includes the 4-fold material changer, but also a single spool holder as included with the A1 (without combo). It takes about an hour to set up the printer on the table.

The printer immediately gives a very high-quality impression, which is mainly due to the choice of materials and high-quality workmanship. The materials are more similar to those used in a DJI drone than in a 3D printer. We cannot say for sure whether the fact that some former DJI employees now work for Bambu Lab is involved in this.

When set up, the compact device in conjunction with the material changer does take up some space. This is also due to the fact that space must be planned at the rear for the print bed movement. The required space should be planned in advance. Due to the hose lengths, there are no plans to position the reel changer anywhere other than next to the device.

After the initial start-up, the printer then carries out some calibration, vibration and noise minimization tests, which look extremely professional but take another 30 minutes or so. The installation of the four spools should also be expected to take a good 15 minutes due to the preheating and nozzle cleaning routines, whereby the printer automatically recognizes the Bambu filament. After this, however, the printer is ready for use and looks impressive without any further delays.

We start printing the pre-saved benchmark with three colors. The system allows color selection directly on the printer before it starts. The noise minimization through noise cancelling is striking, a feature that is not yet commonplace in 3D printers. The vibration-compensating technology and the advanced filament sensor, which not only checks the presence but also the correct flow of filament, are also noticeable during printing. The Benchy is printed with minimal stringing, quickly, cleanly and, above all, in three colors without complications. The color layers are extremely cleanly separated from each other, which is due to the filament cutting and nozzle cleaning process.

Next, we print a three-color panda that contains more complex color layers than the Benchy. This print also produces excellent results and makes the multicolour print really vividly recognizable. However, the more complex color layers also reveal two slight downsides of multicolor printing. Firstly, despite the fast printing speed, the printer takes a long time to complete the print due to the many color changes, and secondly, a not inconsiderable amount of additional material is used to clean the nozzle for almost every layer, which accumulates to the left of the device in the form of small filament drops.

In our test, the A1 Combo showed consistently good results. It is interesting to note that Bambu Lab has brought an entry-level printer onto the market as a second device instead of relying on a larger model. We interpret this as a clear focus on home users. The printer is not only technically appealing, but also attractive due to the surrounding ecosystem. With Maker World, Bambu Lab is working on its own 3D model platform, which is aimed specifically at hobbyists and harmonizes particularly well with its own printers. The associated app allows remote monitoring and control of the printing parameters, including a live video stream of the printing process.

Another interesting aspect are the “Mystery Boxes” that are included with every A1 Mini Combo. These contain electronic components and assembly materials. All parts can be printed out using QR codes in the app and then assembled. This concept playfully introduces beginners to useful applications of 3D printing and expands their understanding of the possibilities of this technology. The quick change of the hotend and nozzle in just a few seconds and the automatic nozzle cleaning before each print are further plus points that make the A1 Combo particularly user-friendly.

The A1 is currently available for around €435 without AMS and around €604 with the AMS Combo. This pricing makes the A1 Mini an interesting option in the entry-level segment, especially when compared to similarly positioned models.

Conclusion

To summarize, the Bambu Lab A1 Combo offers a combination of user-friendly features, innovative technology and an attractive price-performance ratio, which makes it particularly interesting for beginners. However, the main selling point is probably the multi-material functionality of the device, which performed very well in our tests.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.