Until now, the production of customized 3D printing filaments has mainly been the preserve of large companies. However, YouTuber Stefan from CNC Kitchen demonstrates a simple technique that can be used to produce individualized filaments such as multicolor or multipolymer filaments at home.

The starting point was an old 3 mm PLA roll, which Stefan wanted to convert to the more common 1.75 mm dimension. To do this, he used a melting device for PET bottles, through the nozzle of which he pulled the heated 3 mm filament. Different temperatures and tensile forces enabled the filament to be precisely cut to the target diameter.

Stefan transferred this knowledge to multicolor filaments: He first 3D-printed a shape from individual filaments of different colors. He then processed this through the melting nozzle, whereby the colors combined to form a regular multicolor filament.

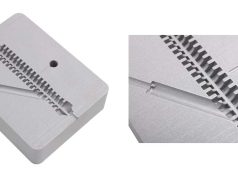

Stefan used a diameter sensor to continuously optimize the process parameters. The process could even be used for special filaments such as partial PLA-TPU filament. In tensile tests, these showed a significantly increased toughness compared to pure PLA.

Microscope images reveal the reason: the TPU forms fibers that act like dampers in the PLA matrix. This makes it possible to create customized composite materials using 3D printing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.