A Chinese-Hong Kong research team has succeeded in developing an aluminum alloy for 3D printing that has exceptionally high fatigue strength. At its core is a dual nanostructure designed to stop cracking.

According to the City University of Hong Kong, the alloy consists of AlSi10Mg powder doped with nanoparticles of titanium boride (TiB2). Printed using the laser powder bed process, the material achieves more than twice the fatigue strength of previous Al alloys, according to the report.

The researchers attribute this to the resulting microstructure. The titanium boride leads to a three-dimensional network of nanoscale silicon phases that form during printing. This structure acts like a cage that prevents crack propagation.

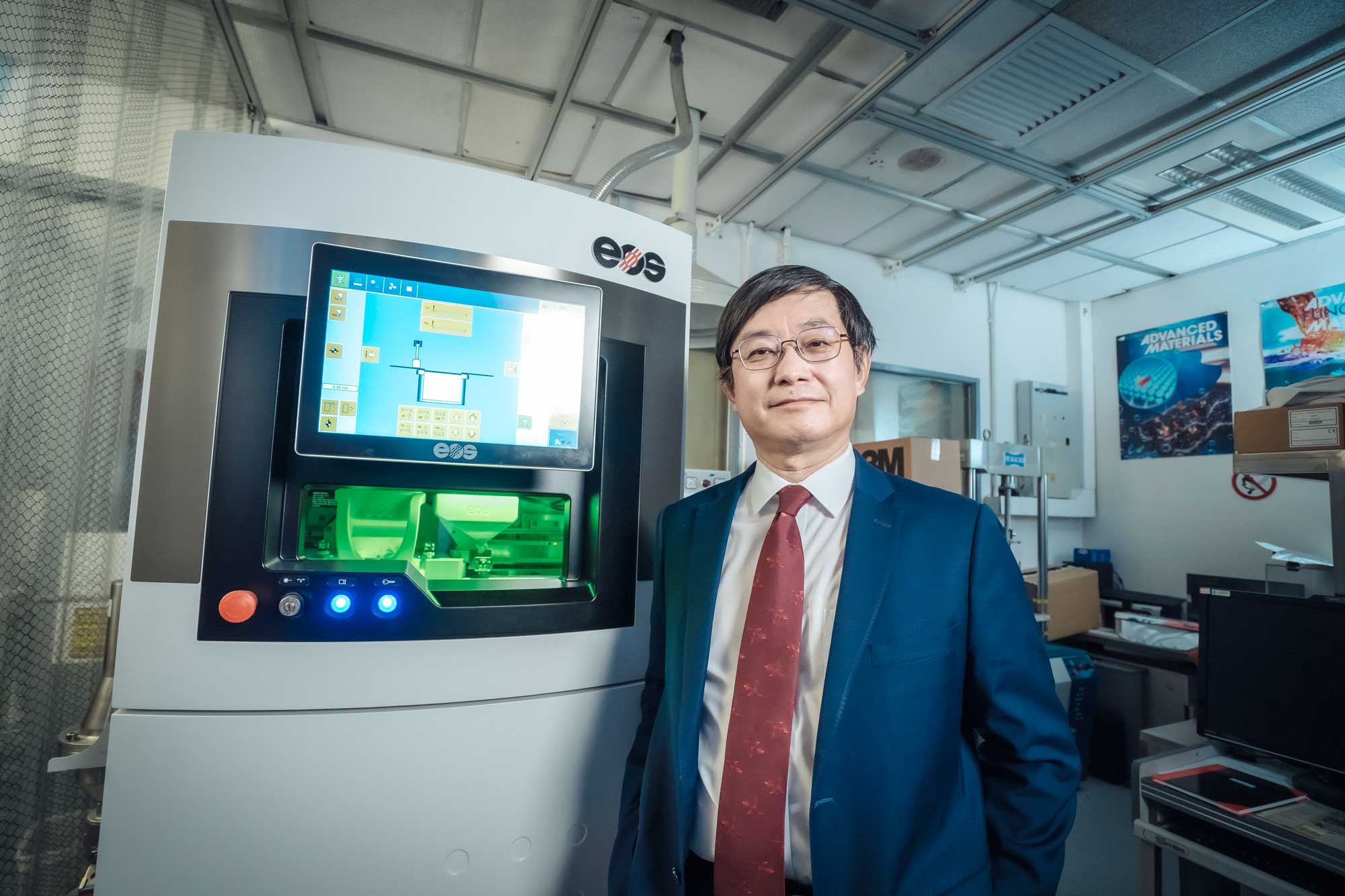

According to the professor involved, Lu Jian, the method can possibly be transferred to other metal alloys to generally increase fatigue strength.

More research is still needed on the practical properties of the new material. But the researchers have already successfully produced prototype turbine blades that passed stress tests.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.