With the aim of boosting both the quality and variation of its application offering to customers, Paris-based service bureau, Erpro Group, has extended its 3D printing capabilities with the installation of Stratasys’ recently-launched full-color, multi-material J850 3D Printer. The integration of the J850 sees Erpro become the first company in France – and one of the first sites in Europe – to access Stratasys’ most-advanced PolyJet™ 3D printing technology to date.

According to Erpro Group’s CEO, Cyrille Vue, the development and production of prototypes and models is very much the heart of his company’s service arm. With the unique capacity to print complex parts featuring seven different materials simultaneously, the J850 strengthens Erpro’s proposition significantly.

“The J850 takes our design expertise to new frontiers insofar as the ultra-realism we’ll now be able to enjoy when 3D printing prototypes for our customers,” he explains.

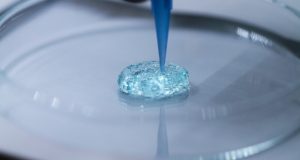

This, says Cyrille Vue, is exemplified by the work undertaken on behalf of the company’s luxury brand cosmetic and fashion customers, such as Chanel, for whom Erpro creates concept bottles and packaging, but also for automotive manufacturers – among them household names like PSA GROUPE and Renault. For Erpro, the J850’s capability to produce advanced translucent and transparent multi-colors, if needed with complicated assemblies, is something his team is keen to exploit.

“We recently established a department to develop prototype head- and tail-lights for automakers and OEM providers, so the ability to use materials like VeroUltraClear™ to offer true-to-life simulation of glass, will enable us to produce prototypes that are literally indistinguishable from the actual final part,” he continues.

Although an established user of other 3D printing technologies, including stereolithography, Stratasys’ J850 extends Erpro’s versatility by directly overcoming one of the company’s long-standing issues – the inability to produce ultra-realistic prototypes and models in several different materials without the need to individually assemble each one. With the unique capability of the J850, this can now be done in a single print.

According to Cyrille Vue, Erpro previously used vacuum casting and overmolding to create prototype car lights. However, the overmolds often delivered imperfect results, typically amounting to shrinkage and defects among the models produced. Additionally, the small quantities of molds required – sometimes as little as just one – made for a costly process.

“In a nutshell, the J850 delivers new impetus to our expertise by enabling us to do things that were previously impossible – and in those instances where we could do it, we’ll now be able to do so much faster, easier and cost-effectively, and to an unprecedented level of quality,” he explains.

Looking ahead, Erpro sees the J850 as pivotal to widening the applications gamut available to the company’s luxury brands, something which the printer’s PANTONE Validated™ color capability will be especially useful. This includes extending the range of prototype applications offered to explore 3D printing onto color packaging and opportunities for printing to textiles, as well as increasing the quantities produced from samples to small series production levels.

“Our company motto is ‘Erpro – Going Beyond Innovation’ and quite simply, Stratasys’ J850 gives us the technology to genuinely and quantifiably deliver on that goal. We believe this will transform the way in which we fulfil the design needs of our customers,” Cyrille Vue concludes.

Established in 1997, Saint-Leu-la-Forêt-based Erpro Group serves customers across automotive, consumer goods, cosmetics and packaging sectors. The company employs 100 people and achieves a turnover of €15 million.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.