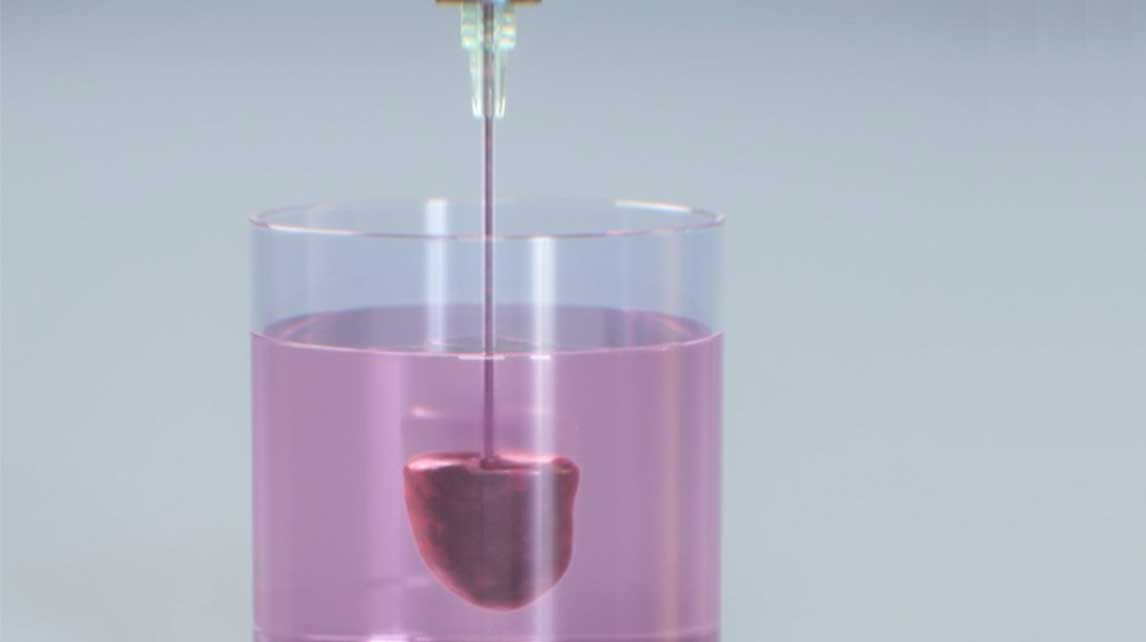

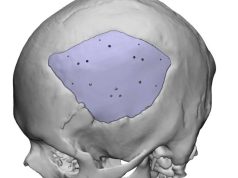

FluidForm Bio, a specialist in the development of lifelike human tissues for the treatment of disease, reports recent advances in the production of human cardiac tissue using FRESH 3D bioprinting.

This approach addresses the urgent need for a predictive model of human cardiac physiology in drug development, as existing models are often inadequate and do not fully represent the complex physiology of the human cardiovascular system.

FluidForm Bio has shown that this deficiency can be bridged by using human induced pluripotent stem cell-derived cardiomyocytes (hiPSC-CMs) in a three-dimensional tissue structure.

“We are not aware of any other biofabrication or tissue engineering approaches that can achieve comparable cell densities and uniaxial alignment on the market today, both of which contribute to more advanced physiologic function” said FluidForm Bio CTO and Co-founder Adam Feinberg.

FRESH technology overcomes many of the limitations of other engineered cardiac tissues by enabling a high degree of cardiomyocyte alignment while minimizing hypoxia and cell death. In addition, the use of robotic manufacturing ensures that the tissues are highly viable and reproducible, and can be replicated across tissues and batches.

“This study was conducted by scientists at FluidForm and Merck & Co.,” explained FluidForm Bio CEO and Co-founder Mike Graffeo. “This is further evidence that we build the most lifelike tissue in the world with FRESH™. As we develop tissue therapeutic applications on this platform, we are thrilled to collaborate with top scientists and look forward to sharing further data.”

These developments demonstrate the potential of FRESH technology and mark an important step in biotechnology and pharmacology, opening the door to more precise and effective treatments.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.