In parallel to the METAV 2016, at the Düsseldorf Exhibition Centre on 24 and 25 February 2016, a specialists’ conference called “Inside 3D Printing” will be held. It will cover the conference’s entire spectrum of additive manufacturing with metals and plastic components. The watchword is no longer printing instead of metal-cutting, but increasingly printing and metal-cutting. Hybrid machines are on the advance: they are extending field-proven metal-cutting techniques to include the multifaceted options offered by additive manufacturing in a single workspace.

The integration of additive manufacturing processes into the metal-cutting operation, in the estimation of Dr. Eric Klemp, Commercial E Director of the Direct Manufacturing Research Centre (DMRC) at Paderborn University, and responsible for the programme of the “Inside 3D Printing” conference at the METAV 2016, offers a series of options and additional benefits for the user. “By combining material build-up and removal in a single machine, functions can be integrated in a way hitherto impossible. For instance, different kinds of material can be used in a single manufacturing process. One additional benefit is that the process incorporates the long years of expertise accumulated by the machine tool manufacturers.” The 3D expert sees further advantages in the options available for mass production and standardisation, plus the aspects of accuracy, reproducibility, production of undercuts, utilising freedom of form, and material savings. Not least, two processes are being merged with each other, which helps to synergise the advantages of both.

Integrating the core competence of additive manufacturing is by no means a trivial matter. In terms of technology, it means another rethink, since fit-for-manufacturing design will in future be accorded even more attention. For this purpose, what’s needed are “smart people who are willing and able to combine the two,” to quote Eric Klemp.

From the METAV 2016, the expert is expecting a fruitful exchange of new and views with the machinery manufacturers, further stimulating input and detailed statements, initial components, and above all a chance to see corresponding machines live in action.

METAV 2016 as a platform for innovative minds

Rainer Gebhardt, Project Manager of the Additive Manufacturing Working Group in the German Engineering Federation (VDMA), sees the advantages of hybrid machines not least in the scope they offer for creative design and machining in a single set-up. All this benefits accuracy levels. It’s generally accepted that most deposited contours have to be reworked. This can be very flexibly implemented in the hybrid machine.

Hybrid signifies in Rainer Gebhardt’s estimation “sensible distribution of additive and subtractive machining. Additive wherever the design demands it, and subtractive wherever the semi-finished product and the volume of the component concerned render a metal-cutting process the sensible choice. Building up large components in an entirely additive process, however, makes sense only if it’s essential – otherwise the combination is better, of course,” adds Rainer Gebhardt.

According to Rainer Gebhardt, the process is an obvious choice for repair jobs in particular. As with all additive manufacturing processes, however, the challenge consists of identifying a suitable application case in the overall environment. To quote Rainer Gebhardt: “You also have to look at the different hybrid processes available – and the costs, naturally. Hybrid also means, of course, that one of the two processes is standing still.”

Some users, says the VDMA’s expert, are accordingly taking a close look at hybrid production. Not in one machine, but certainly the combination of semi-finished product and subtractive manufacturing plus additive manufacturing. This is “precisely what’s exciting about the new technology – in a huge variety of different sectors, innovative minds have taken note, and are trialling solutions. We in the Working Group at the German Engineering Federation bring together precisely this sort of people – from the user sectors and from the technology vendors. This encourages development work on both sides. There’s no shortage of potential – the new processes frequently offer crucial competitive options. The METAV 2016 is an ideal platform for this.”

Another step towards a shorter process chain

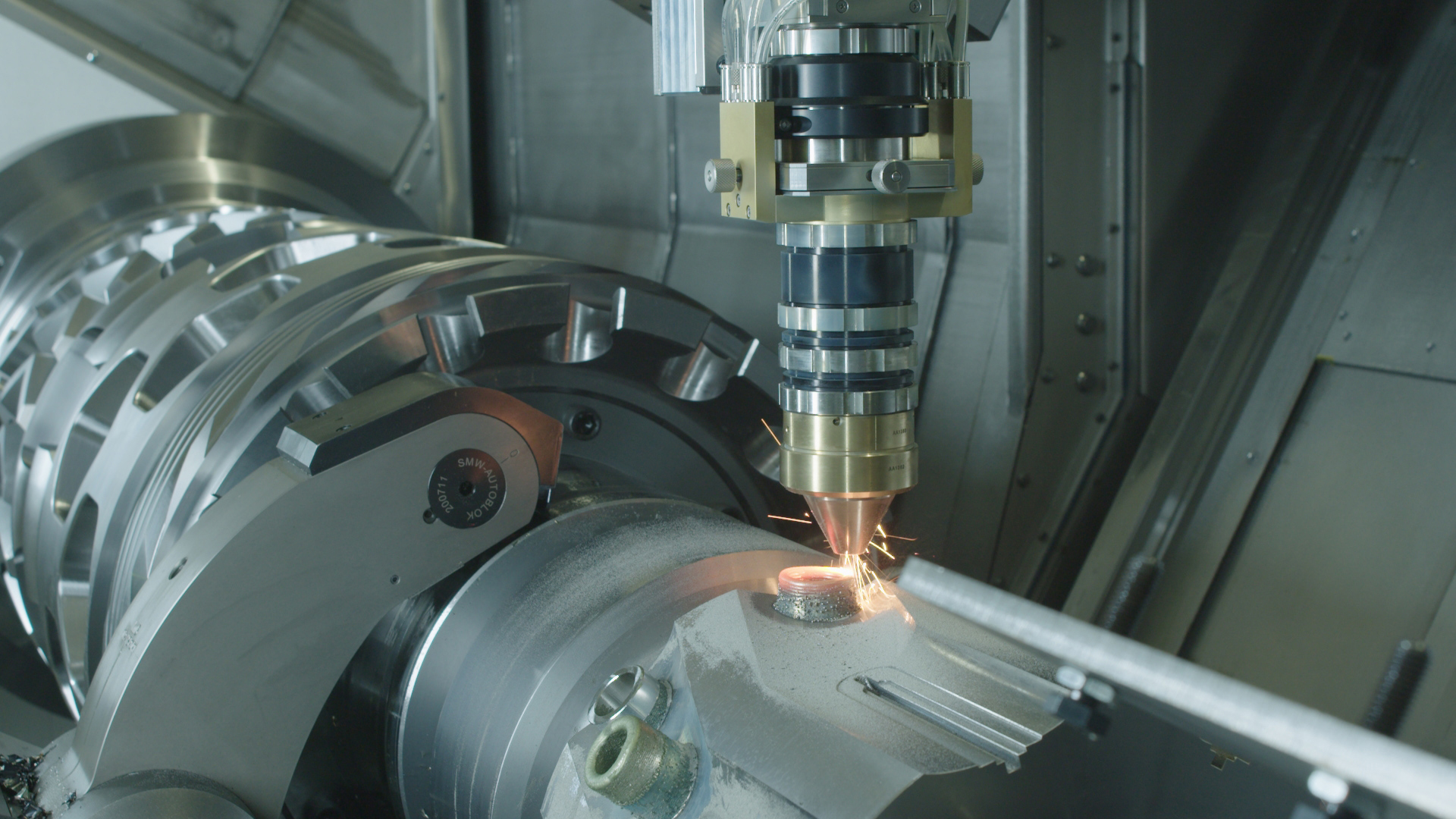

The integration of additive manufacturing processes into a complete machine is explained by Reinhard Koll, Head of Applications Engineering at WFL Millturn Technologies GmbH & Co. KG in Linz, Austria. To quote Reinhart Koll: “We are aiming to integrate a laser without restricting the flexibility of the basic machine.” Special attention is paid here to automatic replacement of the laser unit. This is conditional upon enabling the technology of additive manufacturing to be integrated into the machine without manual interventions. Laser technology complements the machines’ already-existing machining options, so as to shorten and simplify the process chain and thus the throughput time as well.

Worksteps that hitherto necessitated unclamping and external processes can now be implemented on a single machine. According to Reinhart Koll, this not only produces advantages in terms of throughput time and process control, but also helps to significantly improve component quality and save make-ready costs.

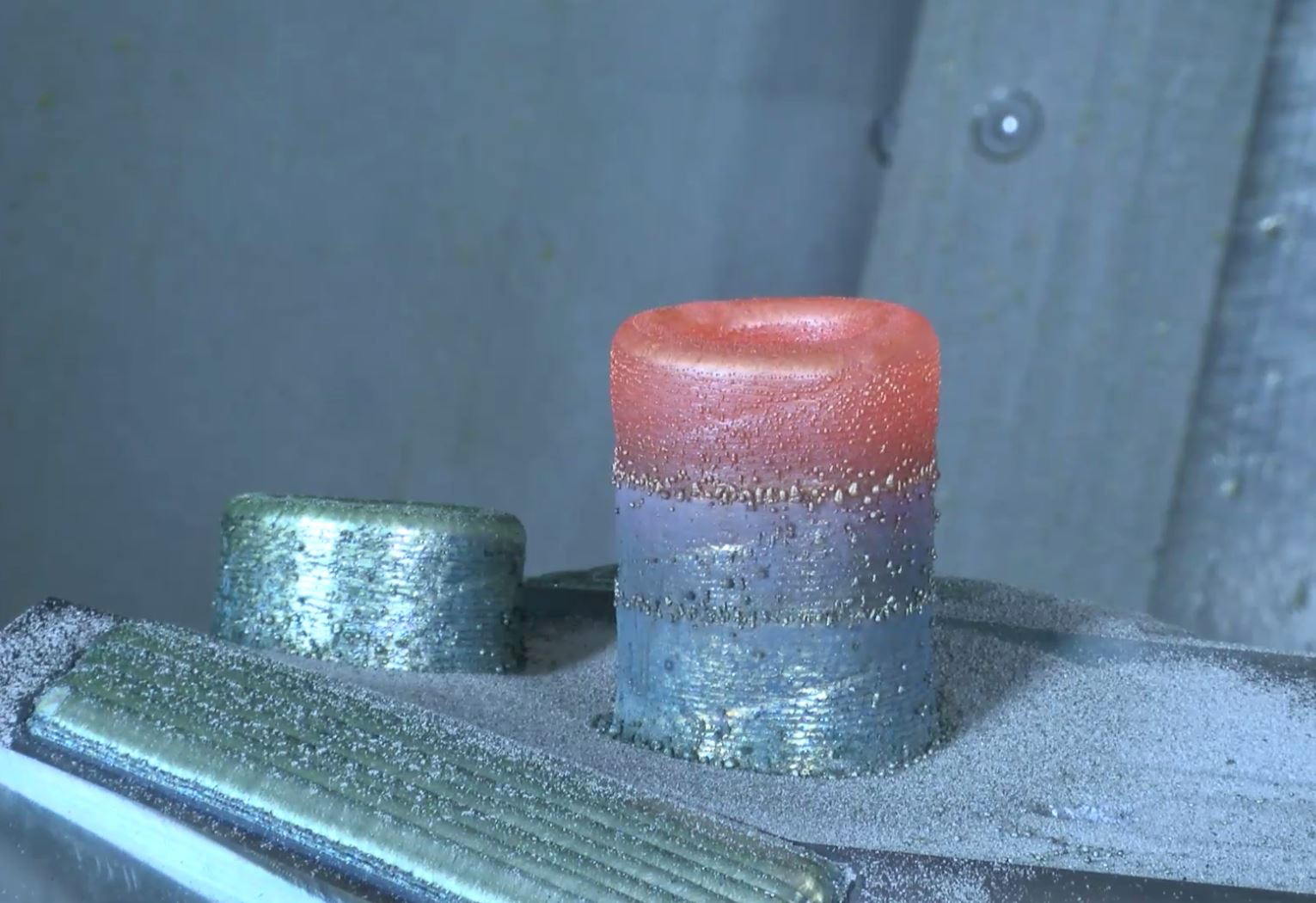

The approach to a process combination of this kind from the viewpoint of the machinery manufacturer, who in most cases possesses competence in metal-cutting, is described by applications engineer Reinhart Koll as follows: “The option of welding, hardening, and material deposition was best imaged by an application for powder laser deposition welding. This technology contains all the requisite elements. The multifarious materials that can be machined using this process, in conjunction with the high deposition rates, constitute optimum preconditions for a broad spectrum of applications.”

The additional benefit for the user is the opportunity to save worksteps. Further technologies, like welding, hardening and coating, are available for specialised machining jobs in addition to the basic technologies in the machine. Manufacture of complex geometries that are difficult or even impossible to create using conventional processes is now within reach. In the case of geometries that protrude from the workpiece, overdimensioned blanks can be dispensed with. This saves machining time, and enables the user to continue working without reclamping with metal-cutting processes. In the case of expensive or difficult-to-machine materials in particular, this aspect should not be underestimated. To quote Reinhard Koll: “Besides creating geometries, the coating of functional surfaces with corrosion-proofing or anti-wear layers is an additional benefit that is of interest to many users.”

Typical application categories include coating worms, rotors, screw spindles, hardening bearings, toothing systems, sealing ring seats or repairing expensive damaged workpieces. Currently, adds Reinhard Koll, “some specific application options are being analysed with interested parties. However, it’s not easy to estimate in which sectors this technology will become established in the medium and long term”. Many design engineers and manufacturing firms have had their eyes opened to new and hitherto unknown options. “There’s a thinking process ongoing here, which will substantially influence the future potential of this technology,” to quote the WFL expert. The Additive Manufacturing Area at the METAV 2016 will also be making a contribution here.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.