CRP Group and Krone Golf combine additive and subtractive manufacturing techniques to create the word’s most advanced golf driver.

To Tiger Woods it’s «the game for a lifetime, a combination of physical, metaphysical, and psychological practices», to George Cole’s character Arthur Daley it’s «like a love affair: If you don’t take it seriously, it’s no fun; if you do take it seriously, it breaks your heart»: this is golf, a «game of confidence, and most important, concentration: the ability to focus and block out distraction» (Joseph Parent, Zen Golf, Mastering the Mental Game).

The aim of this case study is to illustrate the construction of CNC machined and 3D Printed driver clubhead on behalf of Krone, the world leader in custom engineered golf equipment.

Krone ranks among the top international names in the world of high profile golfing; CRP Meccanica and CRP Technology, both part of Italy-based CRP Group, were chosen to work alongside it as technical partners.

The CRP Meccanica and CRP Technology expertise encompass the use of Additive Manufacturing, high-precision CNC machining, non-destructive testing during process phases, CMM dimensional

controls to guarantee the total and complete traceability of every part, from the certification of the metal alloy to the certification of final testing.

THE STORY SO FAR

Titanium and composite materials have been used in the golf industry for nearly 20 years. However, very little has been done over the years to take full advantage of how they are used to optimize the design or part performance. Most efforts have been to reduce cost and increase output: titanium parts are typically cast, stamped, or forged as well as composites are laid up by hand using “pre-preg” (pre-impregnated) and cured by compression molding or in an autoclave.

Krone was determined to create the world’s most advanced high-performance golf equipment. In order to do this Krone CEO Marc Kronenberg and his staff believed they needed to achieve 2 things:

- Break out of the traditional “mass produced” manufacturing techniques and be the pioneers of “mass customization” in the golf industry.

- Use the most innovative materials, high tech processes, and partner with industry leaders in manufacturing to develop a golf driver that sets a new standard for quality and performance.

Krone has done extensive research and testing of different additive manufacturing processes such as Direct Metal Laser Sintering of titanium and 3D printing of “wax” or master patterns for casting: while some of the results were quite promising there were also quite a few issues with accuracy (tolerances), repeatability (part to part variations) , and part quality (surface appearance).

Krone selected CRP Group for the project to provide guidance on how to combine the use of Additive Manufacturing and High-Precision CNC machining.

By partnering with the Italian-based group, Krone was tapped into a network of companies that provide a wide range of custom solution. Two specific divisions within CRP Group were placed on the project team: CRP Meccanica and CRP Technology.

CRP Meccanica coordinated the project between Krone, CRP Technology and the design consultants leveraging its High-Precision CNC machining expertise.

The department of 3D Printing and Additive Manufacturing of CRP Technology creates end parts and prototypes in short time: it can build extremely complex geometry that cannot be easily tooled or it is impossible to tool thanks to the reinforced performing laser sintering powders for

Additive Manufacturing named Windform materials. Their mechanical properties make them a layer above 3D Printing, leading from rapid prototyping to rapid manufacturing.

EVALUATION CRITERIA

There are a lot of metrics used to evaluate golf club performance: most commonly “distance” and “launch conditions” like loft, spin, and ball speed that are easily measured and quantified.

There are also more nuanced ones like “sound” and “feel” that are more of a personal preference take time to fine tune.

Performance is critical as well. Golfers will simply not use a product that does not perform up to their expectations.

That’s the reason why golf club design and development is quite similar to high performance automobiles in that acceleration and top speed are easy to measure, but getting the balance, handling, and exhaust note just right require a blend of art and science.

EFFORTS INVOLVED IN THE COMPONENTS

The engineering behind a great golf driver involves optimizing thickness of each surface, controlling total weight of the head, and tuning the center of gravity of the assembly. It’s a balancing act to get everything right.

The USGA and R&A (Rules Committee for Professional Golf) have placed limitations on the maximum size and volume that a golf driver can be – so engineers are constrained to design within a certain “box”. This has held back innovation and lead to the major golf club manufactures to design product that is all very similar to one another.

«We see – commented Marc Kronenberg – the opportunity to do something revolutionary in the golf industry and design a superior product through the use of intelligent design, innovative materials, and high tech manufacturing methods».

CONSTRAINTS OF PAST TECHNOLOGIES FOR KRONE

Past technologies require:

- machine tooling that limits the geometry that can be produced and

- Labor intensive

- Past technologies are expensive and

- are not suitable for small runs or customized parts

- Casting and Forging have wide tolerances, part-to-part variations, and require secondary operations

Besides titanium cannot be cast or stamped any thinner, due to the need to post-weld parts together.

Welding creates a heat effected zone and can cause deformation in thin areas.

Carbon fibre parts cannot become any stiffer without switching to expensive high modulus fibres.

High-performing CNC machining and Additive Manufacturing solve all of these issues: CNC machining allows to control tightly the thicknesses in critical areas. Additive manufacturing allows to create very stiff lightweight structures and 3D lattice geometries that were never before possible.

“In our working experience with CRP so far – stated Marc Kronenberg, Krone CEO – we have not had any of mentioned issues. The part quality, consistency, and accuracy from both their CNC Machining and 3D Printing Departments has been outstanding”.

KD-1: WINDFORM SP 3D PRINTED DRIVER CLUBHEAD WITH PRECISION MACHINED TITANIUM HITTING SURFACE

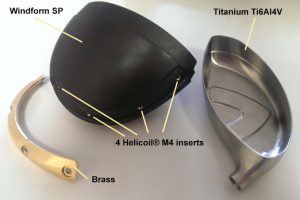

The collaboration between Krone, CRP Technology and CRP Meccanica led to the creation of KD-1. It is a composite driver clubhead where the different materials have a specific function and structural competence.

The KD-1 body structure has been manufactured by CRP Technology’s 3D Printing and Additive Manufacturing department utilizing Laser Sintering and the innovative Windform SP Additive Manufacturing material. Windform SP is a highly ductile material with top mechanical resistance. It is used where there is high stress fatigue even in time as type vibration or shock without the risk of breaking. The elasticity helps to absorb these mechanical stress.

The body has 4 Helicoil® M4 inserts at the end to fasten the weight.

The KD-1 face (the striking surface of the head of the club) is made in Ti6AI4V: it has been CNC machined from solid and sand blasted to clean external surfaces by CRP Meccanica; the hosel was also produced in Titanium as well.

The weight is also CNC machined in brass from solid and sand blasted by CRP Meccanica.

Ti6AI4V TITANIUM ALLOY

CRP Meccanica’s chosen a lightweight but durable material for this type of product, namely Ti6Al4V titanium alloy.

The Titanium alloy used by CRP Meccanica also satisfies the need to have parts that comply with weight and size constraints.

The shape of KD-1 face part has made it vital to use cutting edge precision engineering machinery: Krone recognized the superior level of technological expertise at CRP Meccanica, the direct result of its origins in the world of motorsport, an extremely demanding field that expects a level of reliability and precision out of the ordinary.

This is why the work at CRP Meccanica becomes fundamental for any application involving a certain degree of criticality: taking into account the properties of titanium and its applications in different fields, from motorsport to aerospace, from naval to industrial sectors, CRP Meccanica is able to CNC machining Titanium alloys from solid and it has been the first to process these alloys through Rapid Casting.

The international scenario demands a company vision that acknowledges the importance of innovation and CRP Group, that includes CRP Meccanica, has risen to the challenge of globalization by focusing on the ongoing updating of its technological know-how: it is enrooted in the experience gained in over 45 years in the world of motorsport. Its ability to offer cutting edge technological solutions and innovative materials puts it in an ideal position to offer its customers the assurance of quality, reliability and accuracy.

CRP Meccanica works with latest generation materials to make functional and aesthetic parts for customers with the aim of making bespoke parts in a rapid timeframe, by exploiting the full benefit of its specialized in-house technical team, which is involved in projects every step of the way.

ADVANTAGES OBTAINED WITH HIGH-PRECISION CNC MACHINING AND ADDITIVE MANUFACTURING TECHNOLOGIES WITH WINDFORM MATERIAL:

- speed

- precision

- design flexibility

- part optimization

The most interesting features about parts realized in Windform SP and High-Precision CNC machining is that the process is very lean and direct: once the CAD file is verified, the process just requires a bit of programming and set-up, before the parts are directly made on High-Precision equipment (CNC and SLS) that can virtually run 24 hours a day. The finished parts are high quality and match the original CAD file exactly.

The combination of 3D printing and CNC machining leads to speed up the manufacturing process of the parts and save time. The additive manufacturing technology is much faster than designing and producing a tool for injection molding. Furthermore, 3D Printing can give engineers more flexibility in the timeline to make design improvements.

“We plan – Kronenberg added – to continue to work closely with CRP to refine the design so that it can take full advantage of their CNC and Additive Manufacturing processes and bring the concept of “mass customization” for individually made golf components to market by the end of this year.

The fit between the CNC machined parts and the Windform is exactly as designed. I can say from the design point of view that the use of Windform SP and titanium has allowed me to really push the limits for the “performance” of the golf club: its performance level, as predicted in computer simulations, is unlike any other golf club available today”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.