3D Lab is revolutionizing the production of high-sphericity metal powders with its ATO atomizers. Originally developed for universities, research institutions and service bureaus, ATO technology is gaining traction with industrial users thanks to its reliability and repeatability.

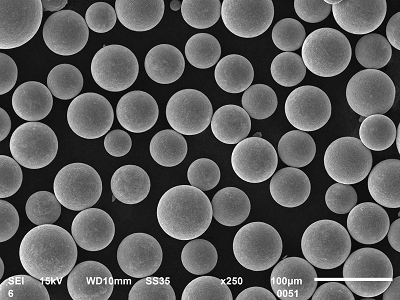

ATO technology uses ultrasound to break down molten metal into fine droplets that rapidly solidify into metal powder under an inert gas atmosphere. The powder size depends on the ultrasonic frequency used, with higher frequencies producing smaller particles and lower frequencies producing larger particles. It can also process different input materials such as wire, bars, pellets, granules or scrap.

Two ATO machine models – ATO Lab Plus and ATO Noble – are distributed in France by Multistation. The major advantage of these machines is their compact size, the ability to produce small quantities, and an affordable price.

3D Lab has already sold over 60 machines worldwide for academic and industrial purposes, including to prestigious institutions and companies such as TECHNION, University of Brno, University of Maribor, ETH, CEA, Mitsubishi and Panasonic. With Multistation at their side, 3D Lab aims to increase these sales figures.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.