Neotech AMT GmbH of Nuremberg, Germany has announced two new major projects to expand on the capabilities for Fully Additive 3D Printed Electronics (3D PE): In the EU PENTA project “Hyb-Man”, 11 partners from Germany and the Netherlands will develop hybrid 3D manufacturing methods to enable flexible first time right production of smart systems.

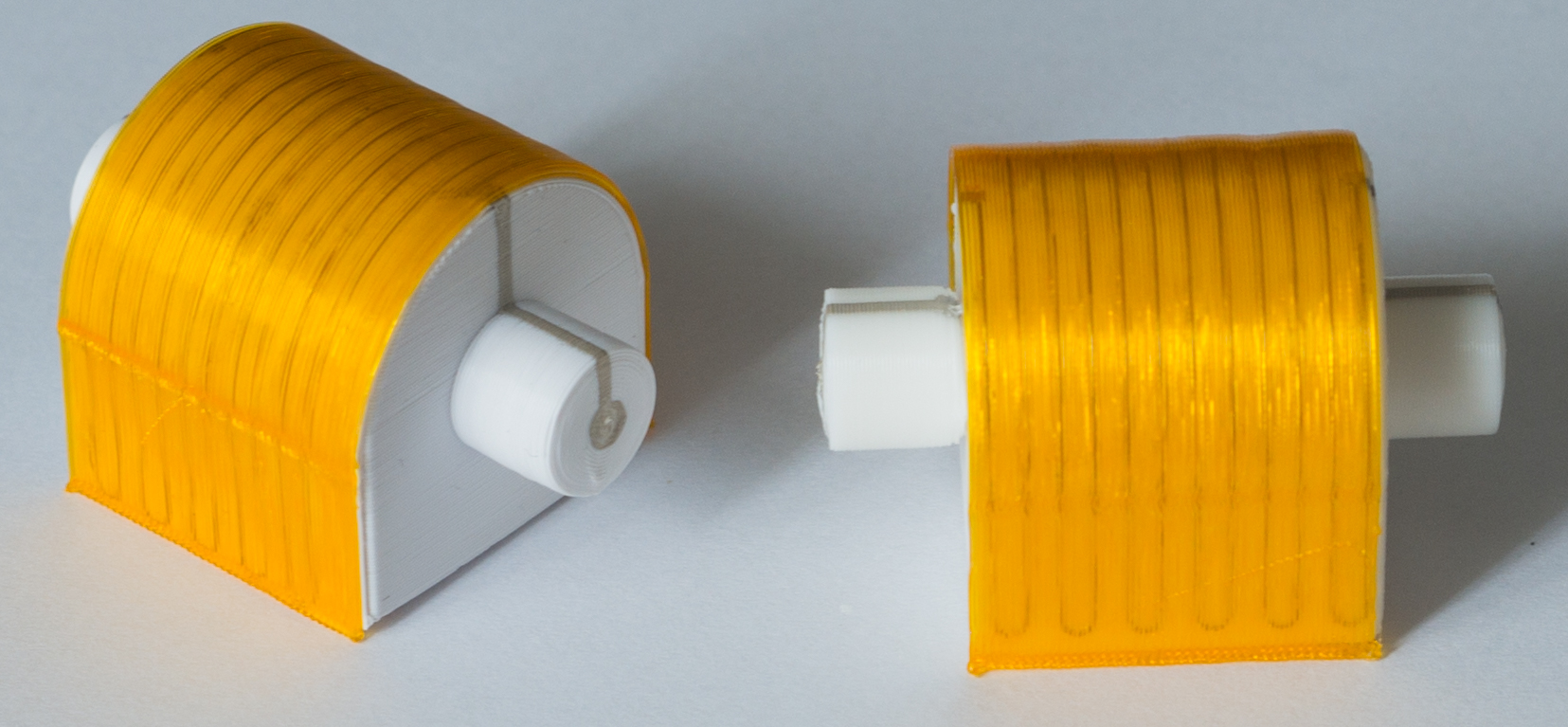

The new hybrid 3D manufacturing will exploit 3D Printing of polymers in combination with 3D Printed Electronics as core production technologies. In-line testing and quality monitoring processes will be integrated as part of the complete process chain. The outcome of the project will be improved Additive Manufacturing processes, a hybrid manufacturing production cell and prototypes of integrated electrical products (LED luminaires, automotive adaptive sensors) made using the hybrid manufacturing cell.

In the second major project, AMPECS funded by EU Manunet Program, fully additive manufacturing process for 3D Printing Electronics with ceramic substrates will be developed. The German-Spanish consortium will develop 3D printable ceramic materials for creating the structural body and integrate printed electronics into and onto this component. End use applications will cover areas where harsh environments exists such as automotive and aerospace as well as in mobile communications.

Neotech has been developing 3D PE mass production systems for directly writing electronics onto injection moulded parts since 2009 with the first mass production program running since mid-2015. By adding capability for printing structural components in printed plastics and ceramics, these two mutually supporting projects will help drive the adoption of fully additive 3D PE technology.

“Neotech has been pioneering the development of 3D Printed Electronics and our patented technology has a proven industrial track record” explains Dr. Martin Hedges, Managing Director of Neotech. “We have been working on combining 3D Printed Electronics with classical 3D Printing of mechanical structures and these new projects will accelerate the development. The ability to use fully Additive Manufacture to create complete 3D mechatronic systems enables many novel applications across diverse industries. The resultant process lines will address the needs for low volume agile manufacture within a single platform. Furthermore the parallel processing of 4 parts simultaneously will allow AM to scale to higher volume manufacturing than is currently possible, closing the scalability gap on traditional tool based manufacturing methods. ”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.