Software developer Oqton has announced a partnership with Chinese 3D printer manufacturer Farsoon Technologies, which specializes in laser powder bed fusion (LPBF) systems for polymers and metals.

The combination of the technology leadership and expertise of these two organizations is intended to enable a complete manufacturing workflow — from design through production — within a single software solution. As a result, industrial manufacturers will benefit from additive manufacturing solutions that increase productivity and help maximize their innovation and competitive advantage.

Oqton’s additive manufacturing software portfolio comprising 3DXpert, Amphyon, and Manufacturing OS addresses the entire workflow. This includes leveraging 3DXpert for design optimization and toolpath planning, Amphyon for process simulation to improve print strategies, and its AI-powered Manufacturing OS platform running order optimization and scheduling, monitoring, and management.

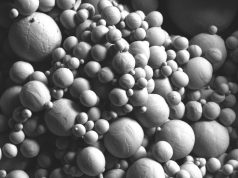

Farsoon’s high-quality, industrial LPBF systems feature a wide range of build envelope sizes and production capabilities. Farsoon machines are renowned for producing high-quality, repeatable parts with excellent mechanical performance, accuracy, and surface finishes. Bringing together Oqton’s software and Farsoon’s 3D printing equipment will provide an integrated solution designed to enable a more streamlined additive manufacturing workflow including scheduling and planning for the workforce, machines, and material across multiple production lines.

Benefits include:

- Increased efficiency: Customers can reduce the amount of time needed to process data with a streamlined solution that includes efficient design, data preparation, simulation, production planning, and monitoring.

- Improved part quality: Through the power of integrated analysis and simulation tools, customers are able to continually improve their printing strategies to produce high-quality parts.

- Complete traceability: Customers operating in highly regulated industries will benefit from full transparency and traceability across their production workflow through manufacturing execution system (MES) and machine monitoring (IoT) capabilities.

“We’re excited to officially recognize Farsoon as a trusted partner amongst a host of forward-thinking industry leaders,” said Toby Wang, vice president, Oqton. “We are impressed with the commercial and technical success enabled by their 3D printing technology. As we move forward, we intend to deepen our technical collaboration, further helping our customers achieve their desired results with improved productivity.”

Wenyu Guo, director of metal product line, Farsoon added, “The partnership with Oqton will offer real value to our customers from additive data design and preparation to production management. With Farsoon’s core strategy of “Open for Industry,” we are excited about the advanced design and engineering possibilities with the integration of Oqton’s additive software solutions.”

Find out more about Oqton at oqton.com.

For more information about Farsoon, please visit farsoon.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.