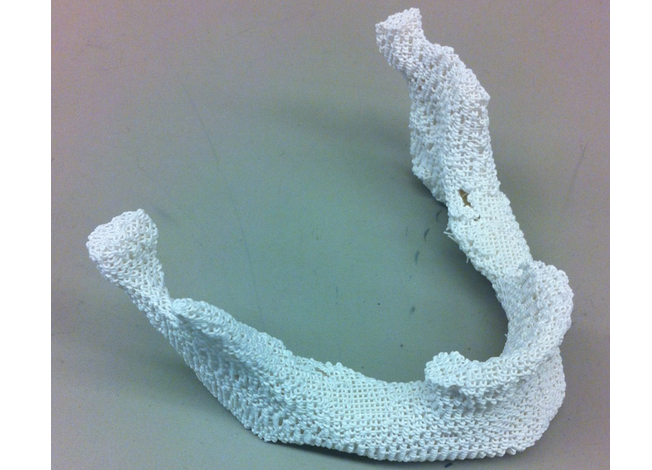

Researchers at Johns Hopkins University School of Medicine have developed a new material for 3D printable bone scaffolds that allow natural bone regrowth when implanted into the human body.

The team led by associate professor Warren Grayson used a mix of the biodegradable polyester material polycaprolactone (PCL), which is FDA approved for clinical applications, and a natural bone powder created by pulverising porous bone inside cow knees after stripping it of cells.

“Bone powder contains structural proteins native to the body plus pro-bone growth factors that help immature stem cells mature into bone cells,” Grayson explains. “It also adds roughness to the PCL, which helps the cells grip and reinforces the message of the growth factors.”

They tested several ratios of the composite material for its printability. A blend of 30% PCL and 70% bone powder performed well, a mixture containing 85% bone powder contained to little PCL to maintain the lattice structure and shape. The 3D printed scaffolds were then used in combination with human fat-derive stem cells. Already after three weeks 70 % of the scaffold showed cell growth and gene activity that was a hundred times higher compared to pure PCL scaffolds.

The scaffolds were then tested in mice with large holes in their skull bones. Mice that received the 3D printed scaffold implants laden with stem cells, showed new bone growths within 12 weeks. Among the different implants tested, scaffold that contained 30 or 70% bone powder showed at least 50 % more bone growth than plain PCL implants.

Instead of cow bone, that is actually FDA approved for clinical use, the researchers plan to test bone powder made from human bone as it is used more widely for clinical applications. Additionally, they aim at creating more natural structures for the scaffolds interior and test additives that encourage new blood vessels to infiltrate the scaffolds. This would allow for thicker bone implants to be made.

The study titled “Three-Dimensional Printing of Bone Extracellular Matrix for Craniofacial Regeneration” was published by ACS Biomaterials Science & Engineering.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.