ZHU Zhiqiang, Prof. SI Ting, Prof. XU Xiaorong and their colleague from the School of Engineering Science, University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS), have recently proposed a new method for patterning soft materials, programmable pulsed aerodynamic printing (PPAP).

Control over generation and patterning of soft materials is essential in biology, medicine, chemistry, and engineering. Droplet-based printing enables precise adjustment of microdroplet size, structure, and composition, and is therefore finding increasing application in fields such as soft robotics and bioprinting.

However, it remains challenging to achieve precise printing on droplets with multiple surfaces over a wide range of Z-numbers, an important index for printing soft materials.

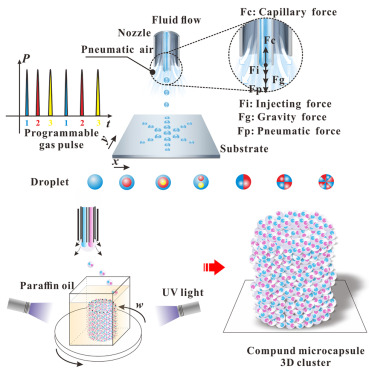

To overcome this challenge, the researchers introduced the PPAP technique. It uses external flow excitation to generate strong shear in droplet microfluidics. The method allows the size of droplets to be reduced and the printing speed to be increased, which facilitates the production of multi-chambered droplets.

The researchers also created a theoretical model to clarify the mechanical principle of PPAP and prove its stability. They see great potential in PPAP for applications such as cell encapsulation, controlled drug release or 3D microstructures.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.