A research team led by Profs. Zhang Zhefeng and Zhang Zhenjun from the Institute of Metals Research of the Chinese Academy of Sciences has developed a strategy to produce a fatigue-free 3D-printed titanium alloy in which the microstructure and defects are regulated separately, known as net-additive manufacturing preparation (NAMP).

Additive manufacturing, also known as 3D printing, is considered a groundbreaking technology in the manufacturing sector. However, the poor fatigue resistance of 3D-printed materials under cyclic loading – compared to traditionally manufactured materials – has severely limited their application as structural components in critical areas such as aerospace and aviation.

In their study, based on previous fatigue prediction theories, the researchers present a new concept: 3D-printed microstructures have a naturally high fatigue resistance. However, the low fatigue performance of 3D materials could be overshadowed by the negative effects of micropores induced by the actual printing process.

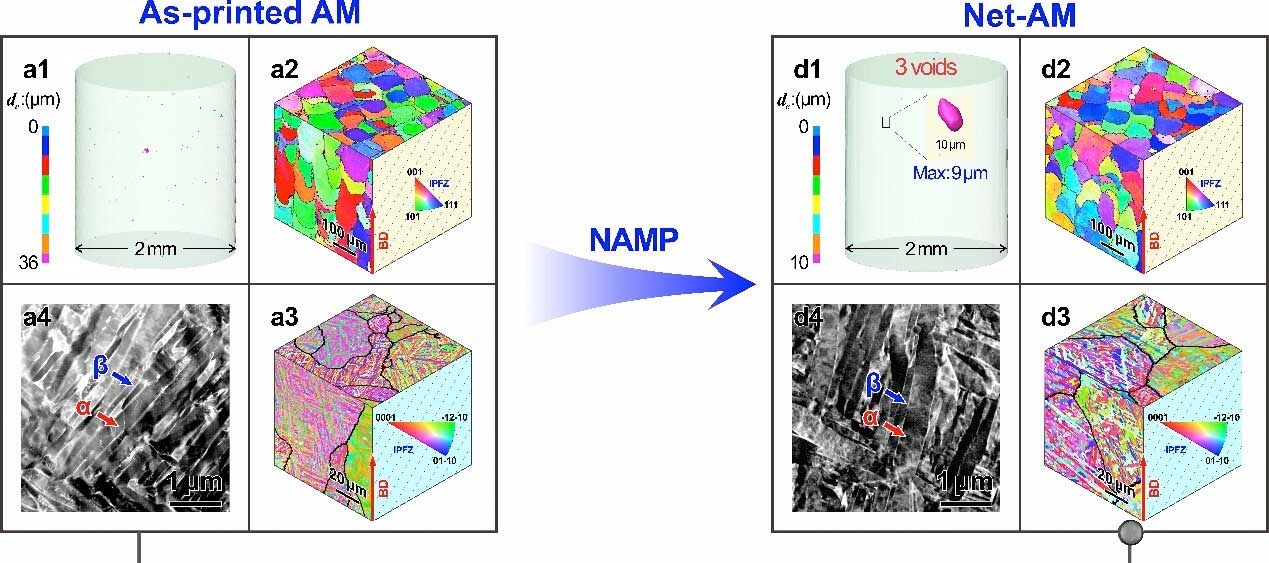

To test this concept, they developed the Net-Additive Manufacturing Process (NAMP), which includes hot isostatic pressing (HIP) to eliminate the micropores and a subsequent high-temperature short-time (HTSt) heat treatment. These processes restore the AM microstructure with fine martensite microstructure, which successfully restores a nearly pore-free Net-AM microstructure in the titanium alloy.

Interestingly, the Net-AM microstructure exhibits remarkably high fatigue resistance, outperforming all other additively manufactured and even forged titanium alloys. It also shows the world’s highest specific fatigue strength (i.e., fatigue strength/density) of all reported materials.

Fatigue cracking of NAMP-prepared microstructures typically occurs at clean primary β-grain boundaries and fine martensite microstructure, which successfully avoids many traditional fatigue weaknesses and prevents localized damage accumulation, resulting in extremely high fatigue resistance.

This study reveals the naturally high fatigue resistance of 3D printed microstructure and the potential benefits of 3D printing technology in the production of structural components. It also identifies clear directions for fatigue strength manufacturing in 3D printing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.