SiCeram and Spectrum Filaments are introducing an innovative series of ce-ramic materials for 3D printing in FDM / FFF technology! Four specialized fila-ments are the first commercial solution of this type on the global market, allow-ing 3D printing of high-tech-ceramic using typical desktop 3D printers.

SiCeram GmbH, a technology oriented enterprise, is applying innovative processes for manufacturing high performance ceramic components. Thermoplastic feedstocks consisting of ceramic powders and polymers allow unique shape forming technolo-gies analogous to polymers: injection molding, extrusion and warm pressing.

Spectrum Filaments is manufacturer and supplier of high quality filaments for 3D printers operating in FFF/FDM technology. Filaments manufactured by Spectrum are characterised by a comprehensive range of properties and applications, ranging from high performance to unique aesthetic solutions.

3D-printing is a new additive forming technology for ceramic components. It will find its application mainly for fabrication of prototypes, small series or complex geome-tries, with internal hollow spaces e.g., which are not able to be produced by other techniques. A big advantage is seen in the free choice of over-size factors which allows to adapt different shrinkage values during sintering. An adaption of linear shrinkage for conventional shape forming technologies such as dry pressing or in-jection moulding always means high costs for adapting the tools. In case of 3D-printing an additional component is simply printed using modified over-size factors.

The ceramic filaments for 3D printing are based on a polyamide as binding phase, which distinguishes them from other, related filaments for 3D printing using metal powder, which are based, for example, on relatively toxic POM. Ceramic filament prints at very low temperatures, at 150-170°C with a bed temperature of 40-50°C.

The shape forming by the printer is followed by the usual processing steps such as de-binding, sintering and hard machining, if necessary. It is always feasible to ma-chine the printed components in green state in order to minimize the hard machin-ing. By using a thermoplastic recipe the green components exhibit a high green strength and thus can be worked with almost no risk of pre-damages.

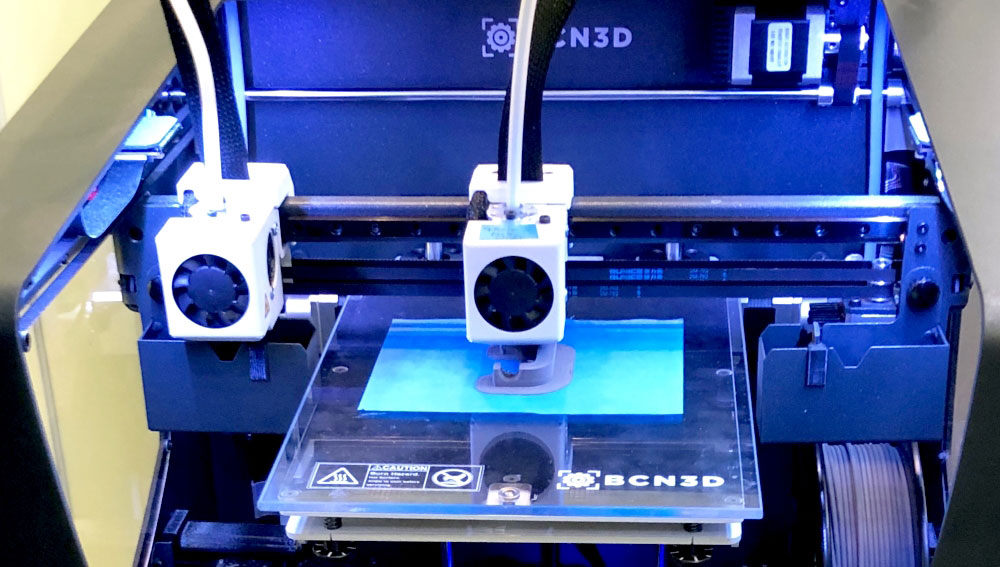

All 3D models that will be presented next week at Formnext 2019 were printed on a BCN3D Sigma 3D printer, which confirms that materials are suitable for the desktop 3D printing environment.

SiCeram and Spectrum Filaments manufacture filaments for 3D-printing on basis of the most common materials of high tech ceramics.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.