A team that includes researchers from Penn State University recently printed a turbine component made of ceramics that are more heat-resistant than conventional metals. The resulting component has complex internal cooling properties that allow it to withstand higher temperatures, increasing fuel efficiency.

The team will present their methods and results at the ASME 2023 Turbomachinery Technical Conference and Exposition, which will be held June 26-30 in Boston. Their work will be published in the conference proceedings and has also been recommended for publication in the ASME Journal of Turbomachinery.

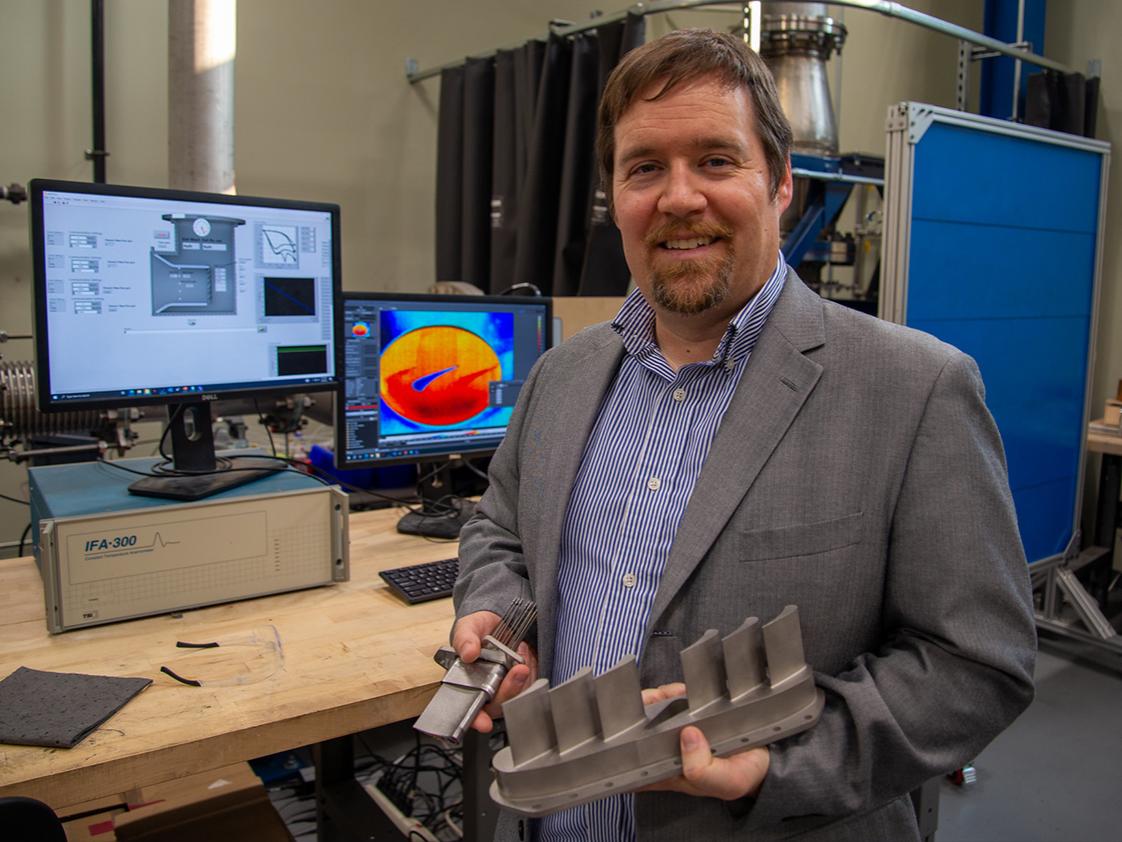

“There is a fair amount of research on ceramic materials for gas turbines, but not a lot of it has generated realistically shaped parts because the manufacturing is so difficult to do,” said paper co-author Stephen Lynch, associate professor of mechanical engineering at Penn State. “This process was unique in that we could generate complex-shaped parts very easily and very cheaply.”

The researchers used design optimization and a novel 3D printing technique to print more heat-resistant blades from a ceramic material derived from polymers.

“We worked with collaborators at the Colorado School of Mines and the University of Wyoming who had embedded ceramic fibers into additively printed ceramics,” Lynch said, explaining that these polymer-derived ceramics are created by firing a plastic-like base in a furnace. “We adapted that to create these turbine airfoils, but also leveraged the design freedom of additive manufacturing to create internal features that dramatically improve the effectiveness of the cooling air inside the blade.”

By 3D printing and using ceramics derived from polymers, the researchers were able to create the shapes needed for greater heat resistance and good performance in the gas turbines.

“We found that with the right design for the part, the ceramic airfoil shape that we 3D printed can perform just as well as the metal components,” Lynch said. “Our hope is that this technology could be used to develop ceramic parts that perform similarly to metallic parts in gas turbine engines but can tolerate higher temperatures for greater fuel efficiency.”

The other authors on this paper were Andrew Fox, graduate student in mechanical engineering at Penn State; Jason Young and Carl Frick of the Colorado School of Mines; and Jennifer Hankins, Kyle Kuhn, Stephan Brinckmann and Ray Fertig III of the University of Wyoming. Michael Hickner, the Craig A. Rogerson Endowed Professor in the Michigan State University College of Engineering currently, and professor of materials science and engineering, of chemical engineering and of chemistry at Penn State at the time of the research, also contributed to the project.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.