Materials engineers at Stanford University have produced tens of thousands of difficult-to-make nanoparticles using a 3D printing process that has long been thought to produce promising new materials that change shape on the fly.

The shape of the nanoparticles is critical to the properties of the resulting material. Wendy Gu, assistant professor of mechanical engineering, and her team used a 3D nanoprinting technique to produce tens of thousands of these complex nanoparticles that can self-organize into different crystalline structures. This ability to rapidly switch between states by rearranging the particles into new geometric patterns is similar to the atomic rearrangement process that turns iron into hardened steel, and could have applications in many engineering fields.

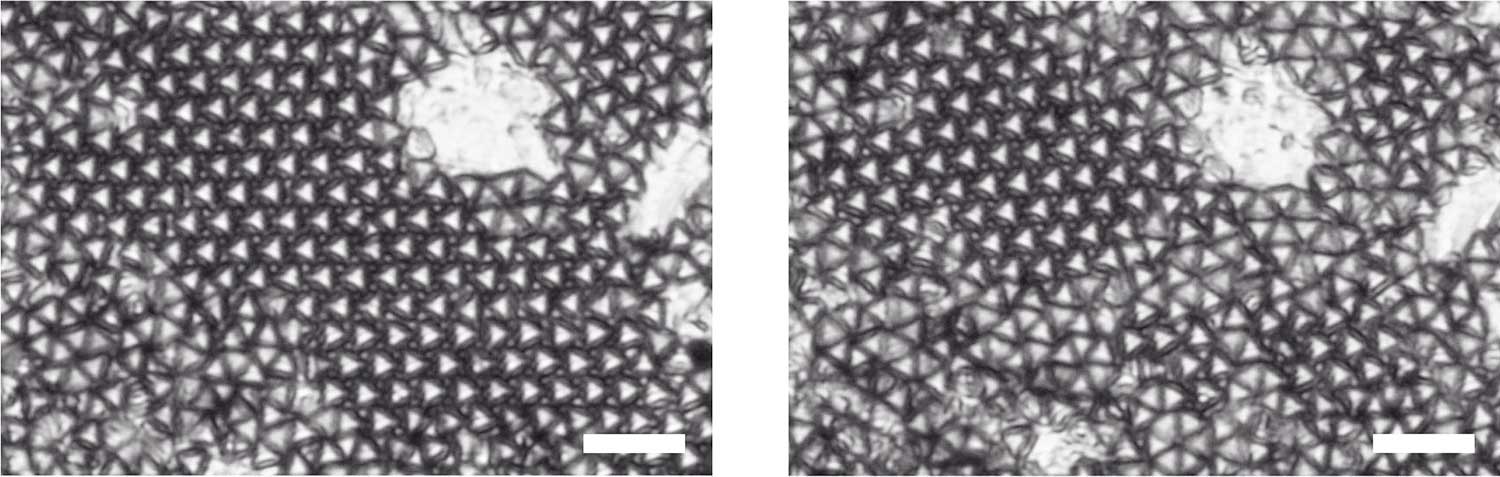

“A crystal made of nano-ball bearings will arrange themselves differently than a crystal made of nano-dice and these arrangements will produce very different physical properties,” said Wendy Gu, an assistant professor of mechanical engineering at Stanford University, introducing her latest paper which appears in the journal Nature Communications. “We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off.”

Specifically, the Archimedean truncated tetrahedra form two important geometric structures: a hexagonal pattern, in which the tetrahedra rest flat on the substrate, and a quasi-diamond structure, which is considered the “Holy Grail” in photonics and could potentially open up new scientific directions.

“With 3D nanoprinting, we can make almost any shape we want. We can control the particle shape very carefully,” Gu explained. “This particular shape has been predicted by simulations to form very interesting structures. When you can pack them together in various ways they produce valuable physical properties.”

Future materials made from these 3D-printed particles could be quickly restructured by applying a magnetic field, electric current, heat or other methods, enabling applications ranging from self-aligning coatings for solar panels to new types of memory for computers.

“Right now, we’re working on making these particles magnetic to control how they behave,” Gu said of her latest research already underway using Archimedean truncated tetrahedron nanoparticles in new ways. “The possibilities are only beginning to be explored.”

This research, supported by the National Science Foundation and the Stanford Graduate Fellowship, demonstrates the immense potential of 3D nanoprinting technology and lays the foundation for future innovation in materials science and beyond.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.