The Zeitgeist has arrived: 3D Printed Footwear

One of the spaces where 3D printing has the most potential for immediate impact is in footwear. In the past year we have seen various announcements about 3D printing of shoes including Kickstarter campaigns, and major players like Nike and Adidas. 3D Printing has obviously hit a tipping point in the field in terms of print quality and material stability.

In many ways, it is a bit of a surprise that the adoption of 3D printing footwear has had a relatively late adoption. Our feet, more so then many of our other body shapes, are uniquely shaped. And we can all probably point to sticking with certain brands simply because the shape of their shoe matched the shape of our foot, irrespective of the style or color of the shoe. And there are at least the same number of women that have chosen a shoe based on the style or color only to have their “individualized” foot suffer the consequence.

Lifespan of Shoes

But shoes also have a second unique marker in terms of clothing and that is the rate they are worn through. Most runners will recommend switching out shoes after 500 miles (800 km). Depending on how far you are running per week, that can often be 3-6 months. Shoes that are worn on a daily basis often don’t fare too much better, depending on the activity of wear a shoe sole can often be worn to replacement within 1-2 years.

What becomes of the waste?

A Vision of the Future of Footwear

The Netherland’s based SLEM, one of the thought leaders in terms of footwear, is taking the lead in approaching the both problems. In 2015, they presented at the GDS Trade Show in Duesseldorf as the only company presenting industrial-grade shoe production using 3D printing. In 2016, they wanted to set the bar a notch higher with the question – how can we continue to customize shoes with 3D printing and become a sustainable alternative to current production.

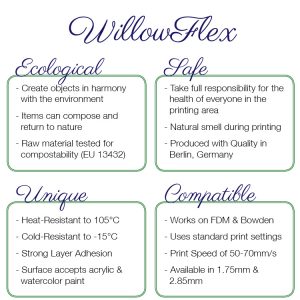

The answer came from BioInspiration, the German-based producer of WillowFlex, the world’s first flexible 3D print filament from compostable raw materials. Their Kickstarter Campaign in late 2015 was the first time that a 3D printing could be both sustainable and flexible – meaning it was the first point that it was feasible to be used for producing shoes.

In preparation for the trade show, SLEM printed a series of shoe soles in their trends lab and experimented with printing directly into the fabric to show the potential for melding design and 3D printing into a single production step.

“WillowFlex was an easy material to work with and printed as well as the other chemical based flexible filaments we have been working with. We look forward to working with BioInspiration to improve the long-term durability of the material to prepare for production.”

Nicole van Enter, Creative Director, SLEM

The current production is still only as prototypes to verify the settings and best practices of working with the material. But there is no question that sustainable materials will become part of the palette in footwear production.

SLEM as a Guiding Light

SLEM is known as a thought leader in the footwear industry, and their early adoption of Industrial 3D Printing and Robotics to produce shoes has really put them on the watch-list for the footwear industry. That is why their emphasis on moving towards sustainable materials has also garnered attention on the trade-show floor.

(image courtesy of SLEM)

“BioInspiration is founded on the knowledge that sustainable materials can equal and out-perform the alternatives.

Working with forward thinking groups like SLEM helps to move the needle of public perception towards acceptance. Experimentation with Vision is the key to Progress.”

Brian Crotty, CEO, BioInspiration

Like with the organic food movement, the consumer pressure for products that reflect a social and environmental responsibility will only grow in the coming years – so the companies that can be first to meet those requirements will have a distinct advantage in the field. As production systems develop for 3D Printing shoes, it will provide a direct competition to traditional production and marketing methodologies.

The partnership of BioInspiration and SLEM represents the synergy that comes from matching design quality, customer needs, customization and environmental awareness.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.