A new process for the additive manufacturing with wood allows for up to 85 % wood content and strengths equal to those of conventionally fabricated wood particle products. With these features this so-called Individual Layer Fabrication (ILF) is suited for a wide range of applications in design, engineering and construction.

The wood working industry creates large quantities of residual wood, e.g. in the form of sawdust, wood chips or wood shavings. Additive manufacturing opens up the chance to transform this waste into individualized, high-quality goods. Next to the ecological reasons of using this raw material, applying wood as feedstock in additive manufacturing can help enhance material properties and reduce material costs.

Accordingly, additive manufacturing by the use of wood has gained high attention in the recent years. Consumables for fused filament fabrication (FFF), containing up to 40 % of wood particles, are already offered on the market by numerous suppliers. Also binder jetting using wood particles is feasible and has been commercialized by Forust in a process, where the 3D printed parts gain their final properties in a post-treatment with epoxy resin.

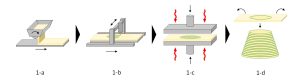

The core idea of ILF: Integrating mechanical pressing into an additive manufacturing process

With the aim of drastically increasing the wood contend in additively manufactured wood composite parts, researchers of Technical University of Munich (TUM) and Fraunhofer Institute for Wood Research (WKI) teamed up to develop a process specifically tailored to this very goal. In this novel fabrication process named ‘Individual Layer Fabrication (ILF)’ parts are built up by laminating successive layers of individually contoured panels, the latter being 3D printed by selective binding of wood particles. As each layer is fabricated separately, mechanical pressure can be applied in the production of these bespoke wood composite panels. This use of mechanical pressing, integrated into an additive manufacturing process, is the core idea of ILF. It leads to a significant increase of the wood content as well as the mechanical strength of the parts fabricated that way.

How the wood 3D printer works: The ILF process in detail

Practically, the ILF process can be described as a combination of binder jetting (where parts are 3D printed by selective binding of particles) and sheet lamination (where objects are built up by laminating contoured panels of solid material), augmented by a work step of mechanical pressing incorporated into the process chain. So by default, Individual Layer Fabrication consists of the following work steps: a) Wood particles are scattered on a base forming a thin layer. b) Adhesive is then applied onto this layer, locally limited to those areas where, according to the target geometry of the object, the particles are intended to be bound. c) The resulting hybrid layer is pressed under heat, thereby curing the adhesive. d) Finally, the unbound material is removed, and the panel of bound particles is laminated onto the stack of previously produced panels. This basic version of the process may be modified in order to increase the effectiveness of the process or to optimize results with regard to specific applications: The order of work steps may be altered, or single step sequences may be repeated several times before advancing to the next step.

3D printed wood by ILF: High strength values and geometric freedom

Parts manufactured by ILF show wood contents of up to 85 mass percent and flexural strengths of up to 50 MPa with densities in a range between 550 and 950 g/cm³. With these features they fulfill or even exceed the requirements for conventionally fabricated wood particle boards. At the same time, the ILF process allows for a high degree of geometric freedom. Individualized, highly complex wood composite parts can be fabricated this way for a great variety of applications. These include e.g. furniture and interior design, load-bearing structural elements, industrial manufacturing devices and packaging. In this video the fabrication of a structurally optimized wooden ceiling element by this novel additive manufacturing process is documented.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.