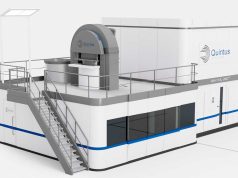

With 888, Ability3D has developed a machine that’s a combination of a metal 3D printer and a CNC milling machine. And the best thing: like most of the professional FDM 3D printers it finds its place on your desktop. The machine was presented to the public at the Maker Faire Orlando for the first time.

Technical the metal 3D printer is only a MIG welding machine that can handle aluminium, steel or stainless steel as welding materials and it is moved by a computer. MIG welding can’t create very exact parts or nice surfaces but therefore the machine has the inbuild CNC milling part. After a layer was printed with the 3D printer its outlines are milled to the exact dimensions.

These technique or a similar one is used more often these days because its more flexible than conventional production with computer controlled machines, it creates less metal waste and there is much less material that needs to be milled.

Metal MIG welding wire is the key to our process. It’s strong, durable, hard and is the perfect material for your 3D printing applications. Using our prototype machine as the test bed for our process, we have developed a way for anyone to be able to print real metal parts in their home or office. Finally everyone has the ability to 3D print real metal parts themselves.

The most interesting thing of the Ability3D 888 is that it needs not very much place and it will cost only about 3,000 Dollars – the same price range as a professional FDM 3D printer. Additional to 3D printing and milling the machine will also be able to work as a small CNC router for wood or plastics. To get funding for the their project the team wants to start an Kickstarter campaign in the first months of 2017.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.