In the “Advanced Processing of Additively Manufactured Parts” (Ad-Proc-Add) project, accompanied by ecoplus Mechatronics-Cluster, researchers systematically investigated additive-subtractive manufacturing (ASM) process chains, delving into the effects of various parameters, strategies, and constraints on material and workpiece characteristics of additively produced components. The esteemed research consortium is now sharing these compelling discoveries with the public.

The project, carried out by nine research institutions from Germany, Austria, Belgium, and Switzerland and supported by a user committee comprising SMEs from all pertinent market sectors, aimed to optimize workpiece properties, such as geometry, surface, and subsurface characteristics, throughout the entire ASM process chain. This visionary goal was pursued to precisely meet the diverse requirements of various industrial sectors.

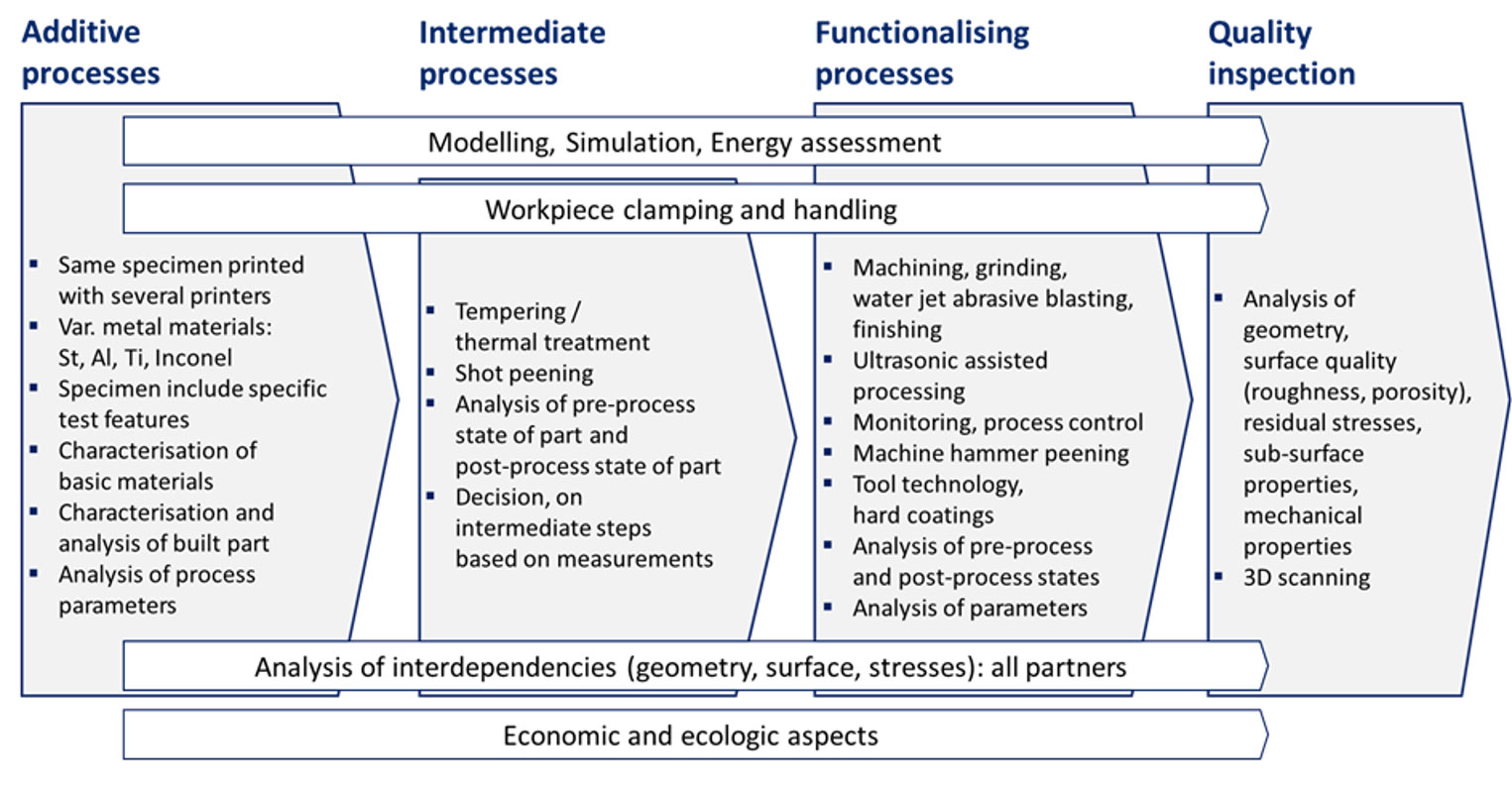

The Forschungskuratorium Maschinenbau e.V. (FKM) coordinated the project, with the Institute for Machine Tools (IfW) at the University of Stuttgart overseeing the technical aspects. An international research consortium was established, bringing together essential expertise in additive manufacturing, machining processes, process monitoring and control, machinery and systems, simulation and optimization, as well as energy efficiency analysis. Utilizing interdisciplinary expertise, detailed experimental studies were conducted to investigate the relationship between parameter settings and their impact on workpiece properties during additive and subtractive processes. These studies yielded valuable insights into physical effects and methods for process monitoring and quality control through correlation analysis.

Based on these findings, researchers developed new tool concepts, strategies for 3D printing metal components, sophisticated post-processing methods, system prototypes for monitoring devices, and additional services, all compiled in a digital compendium.

“Due to the exceptional collaboration with our industrial partners and under the excellent guidance of FKM and IfW, we not only achieved the ambitious goals of the research project, but also produced industrially relevant and applicable results,” states Benjamin Losert, ecoplus project manager of the Mechatronics-Cluster.

The knowledge acquired aids system and service providers in developing new products with enhanced functionalities, while empowering end-users to implement ASM process chains with greater productivity and improved economic and ecological efficiency.

The digital compendium is available for free download from the project website at www.ad-proc-add.eu.

Research partners

- Forschungskuratorium Maschinenbau e.V. (FKM), Germany

- Ecoplus. Niederösterreichs Wirtschaftsagentur GmbH, Austria

- KU Leuven, Belgium

- Inspire AG, Switzerland

- Institute for Machine Tools, IfW, University of Stuttgart

- Institute of Machining Technology (ISF), TU Dortmund University, Germany

- GFE ‐ Gesellschaft für Fertigungstechnik und Entwicklung Schmalkalden e.V., Germany

- Institute for Production Engineering and Laser Technology (IFT), Technical University of Vienna, Austria

- Forschungs‐ und Technologietransfer GmbH, FOTEC, Austria

- Thomas More University College, TM, Belgium

- Sirris, Belgium

- Belgian Welding Institute npo, BIL Belgium

- SIRRIS, Belgium

- Institut für Werkzeugmaschinen und Fertigung, IWF, ETH Zurich

Contact person

DI Benjamin Losert, Projektmanager Mechatronik-Cluster ecoplus.

Niederösterreichs Wirtschaftsagentur GmbH

Niederösterreich-Ring 2, Haus A, 3100 St. Pölten

E-Mail: b.losert@ecoplus.at, Tel.: +43 2742 9000-19669

About ecoplus

As privately run agency with decades of experience, with a highly-specialized team and an expansive network, we offer tailored services to your business. With 16 business parks throughout Lower Austria, we also provide first-class business locations for companies. Our technopols focus on building up technology oriented business locations near existing research and educational facilities. We can also help find access to regional funding and give you a competitive advantage through innovative cooperation’s projects in clusters & platforms that we manage. You can visit the new House of Digitalization in Tulln, which is the flagship project of Lower Austria’s digitalization strategy. In addition, companies from Lower Austrian and abroad can count on our support through the Export / Expat & Relocation Service.

Funding organisations:

Federal Ministry for Economic Affairs and Climate Action, German Federation of Industrial Research Associations eV, Collective Research Networking (BMWK/AiF-CORNET), Austrian Funding Agency (FFG), Confederation Switzerland and Flanders Agency for Innovation & Entrepreneurship (VLAIO).

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.