Metal 3D printer manufacturer AddUp and Airbus Defence & Space have delivered the first metal 3D printer to the European Space Agency. This metal 3D printer was developed by an industrial team led by Airbus Defence and Space under a contract with the European Space Agency (ESA), co-funded by Airbus Defence and Space. The launch on January 30, 2024 with the NASA mission NG-20 was successful.

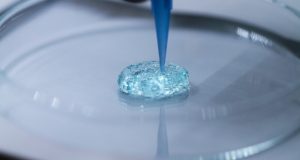

The mission of this 3D printer is to evaluate the capabilities and performance of additive technology in microgravity conditions and to produce metal components in 3D. The ability to produce spare parts directly in space without having to transport them from Earth opens up new perspectives for space travel and makes autonomous operations for human spaceflight feasible.

The “Metal3D” project started in 2016, when ESA awarded the contract to Airbus Defense & Space with the aim of developing the first metal 3D printer that can be safely operated in microgravity conditions on board the ISS. AddUp, a leader in metal 3D printing, has been supporting Airbus Group for over a decade, not only with the supply of flight parts, but also with a variety of innovation projects.

AddUp’s Technical Director, Sébastien Devroe comments on the expertise the AddUp team brought to the project, “The development of the Metal 3D printer relies on the unique multidisciplinary expertise of AddUp’s engineers and researchers. Our staff has expertise across a variety of additive manufacturing processes, machine design, programming and operation optimization. Our teams have supported the development of this first space metal 3D printer, which will soon be in orbit. The metal 3D printer has been designed and optimized to meet the conditions and environment of the International Space Station”

“AddUp was chosen for this project based on a long history and partnership rooted in exploration and innovation”, explains Elodie Viau, Head of Engineering at Airbus Space Systems. “We were confident that with the knowledge and experience the AddUp team has, combined with the technological expertise of Airbus, together we would be successful in delivering a high quality and efficient metal 3D printer to support the exploration of space.”

The printer is to be installed in the ISS at the beginning of 2024 and will be operated in the European Space Agency’s Columbus module alongside other experiments. Four samples are to be printed in the Columbus module and also produced on Earth for comparison. The samples will be brought back to Earth, analyzed and compared with those produced on Earth. The aim is to make metal 3D printing practicable in space, for example for the production of spare parts, and thus reduce the logistics requirements from Earth, which can take up to 12 months between preparation, launch and delivery.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.