A novel laser beam shaping module, designed to address the prevailing challenges in the LPBF process, has been developed at Switzerland Innovation Park Biel/Bienne.

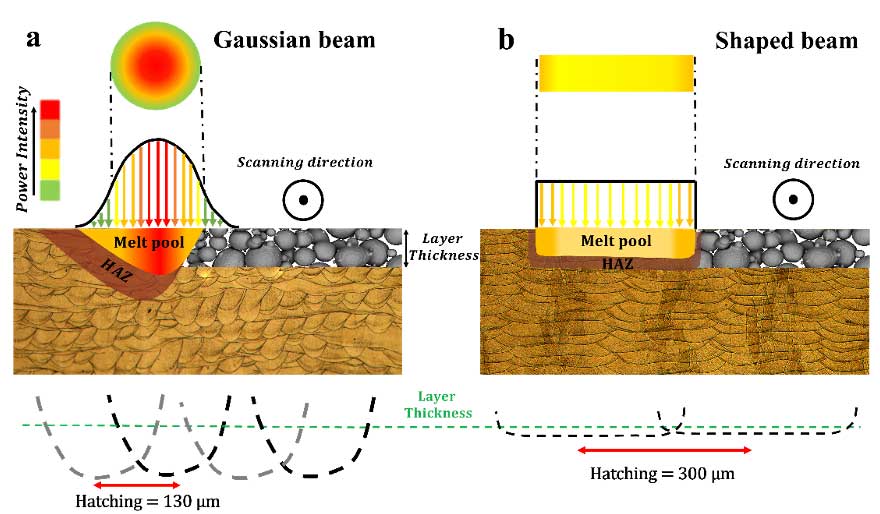

From a processing perspective, a primary limitation of current commercial LPBF machines is the uneven thermal conditions caused by laser beams. Currently LPBF machines utilize Gaussian intensity distributions, which concentrate energy heavily at the beam center, leading to excessive overheating and metal evaporation. Additionally, the lower intensity at the beam edges and the effects of heat conduction prevent material from reaching its melting point. This Gaussian distribution results in the formation of a cone-shaped melt pool, necessitating a small hatch distance to ensure overlap between tracks. However, this diminishes productivity and enlarges the Heat Affected Zone (HAZ) due to repeated reheating. Increasing the total energy density to enlarge the melt pool size is ineffective, as it shifts the melting process from conduction to keyhole mode beyond a certain energy density threshold, causing process instability. The gradient of intensity from the center to the edges of the beam presents a significant challenge, introducing substantial thermal gradients.

In this research, a spatial light modulator device is employed to shape beam, with the goal of achieving enhanced control over temperature distribution and boosting LPBF productivity. This innovative technology facilitates significant optimization of the LPBF process by enabling precise control over the spatial modulation of energy deposition within the material. Consequently, the geometry of the melt pool and the distribution of temperature in three dimensions can be finely tuned. The liquid crystal spatial light modulator utilized in this study serves as a highly efficient active beam-shaping tool, enabling adjustment of transmittance for each pixel to enhance the spatial beam quality of the laser output. With this technology, the 3D printing of metal parts can be achieved with not only increased productivity but also enhanced energy efficiency. This technology, in contrast to the existing beam shaping technologies i.e. ring shapes, enables the forming of limitless laser beam shapes, offering numerous opportunities for different goals and research activities.

In collaboration with an Austrian research group at the University of Leoben, renowned for their expertise in Bulk Metallic Glass (BMG), the application of newly developed beam shaping technology has been investigated for use in the LPBF process of BMGs. High strength, a large elastic strain limit, a low Young’s modulus as well as high corrosion and wear resistance are the main advantages of BMGs. However, the main challenge in the fabrication of BMGs via laser-based additive manufacturing is unwanted reheating and crystallization, which may deteriorate the mechanical properties of the final parts. Therefore, beam shaping technology has been utilized to control the reheating, melt pool geometry and, as a result, reduce the HAZ, which leads to an atomic-scale modification of the amorphous structure. Advanced materials characterizations confirm a nearly fully amorphous structure with enhanced properties currently not achievable by using the state-of-the-art LPBF machines. The schematic of this study has made it to the cover of the Advanced Functional Materials journal.

The full paper entitled “Controlling the Glassy State toward Structural and Mechanical Enhancement: Additive Manufacturing of Bulk Metallic Glass Using Advanced Laser Beam Shaping Technology” can be accessed here.

The project was supported by IRPD AG (Switzerland) and Swiss Innovation Agency (Innosuisse).

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.