Two years ago Alcoa invested $60 Million in the development of 3D printing. Now, they have a deal with Airbus and start delivering plane parts mid-2016.

Alcoa (Aluminium Company of America) is a large American group that is specialised in the production of light weight metals. Two years ago they began looking more closely at their additive manufacturing capabilities. This led them to invest $60 Million into expanding their 3D printing capabilities. Now, they are ready to produce plane parts (fuselage parts and engine pylon parts) for Airbus and will start delivering them mid-2016.

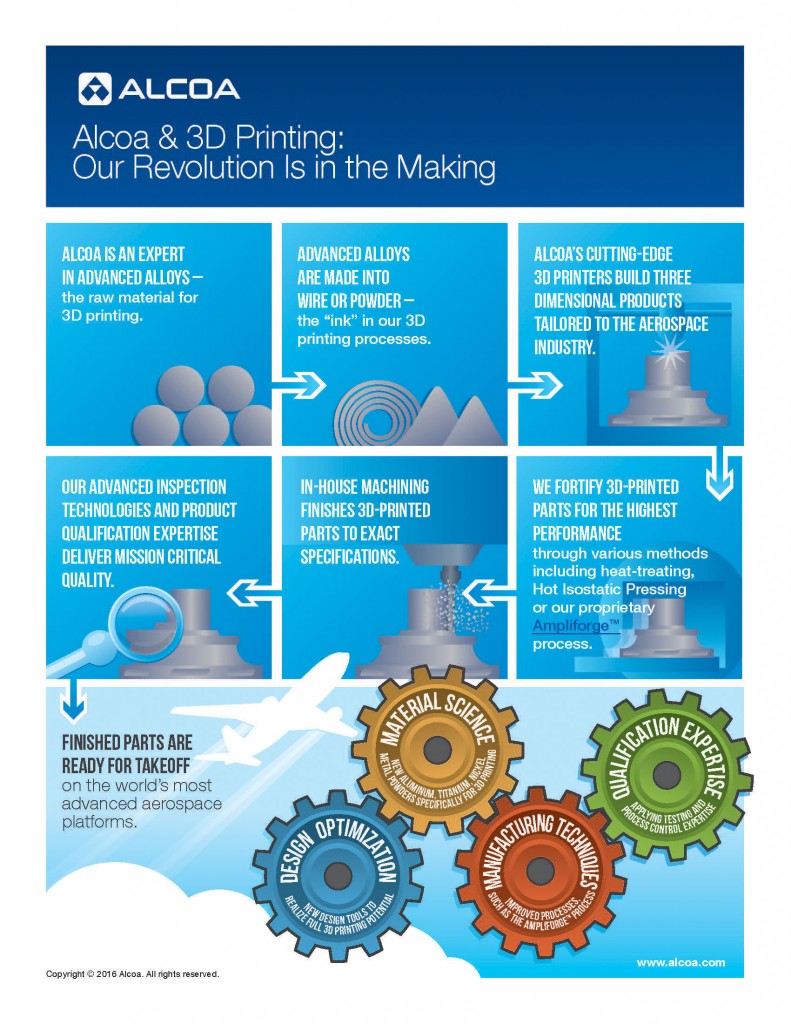

Special aluminium alloys in the form of metal powder or cables are used as base material. Then the parts are formed using 3D printers. Through the use of different technologies the parts created should have the highest quality. Last step of the production is to work with typical metal machines on the parts to ensure all parts fit the specifications. Before the parts are sent to the customer, they undergo a critical quality check.

Airbus has been utilizing 3D printing for some time and since last year Airbus began flying numerous 3D printed parts. This should be a preparation for the development of the Airbus A350 XWB. This plane will be the one with the most 3D printed parts.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.