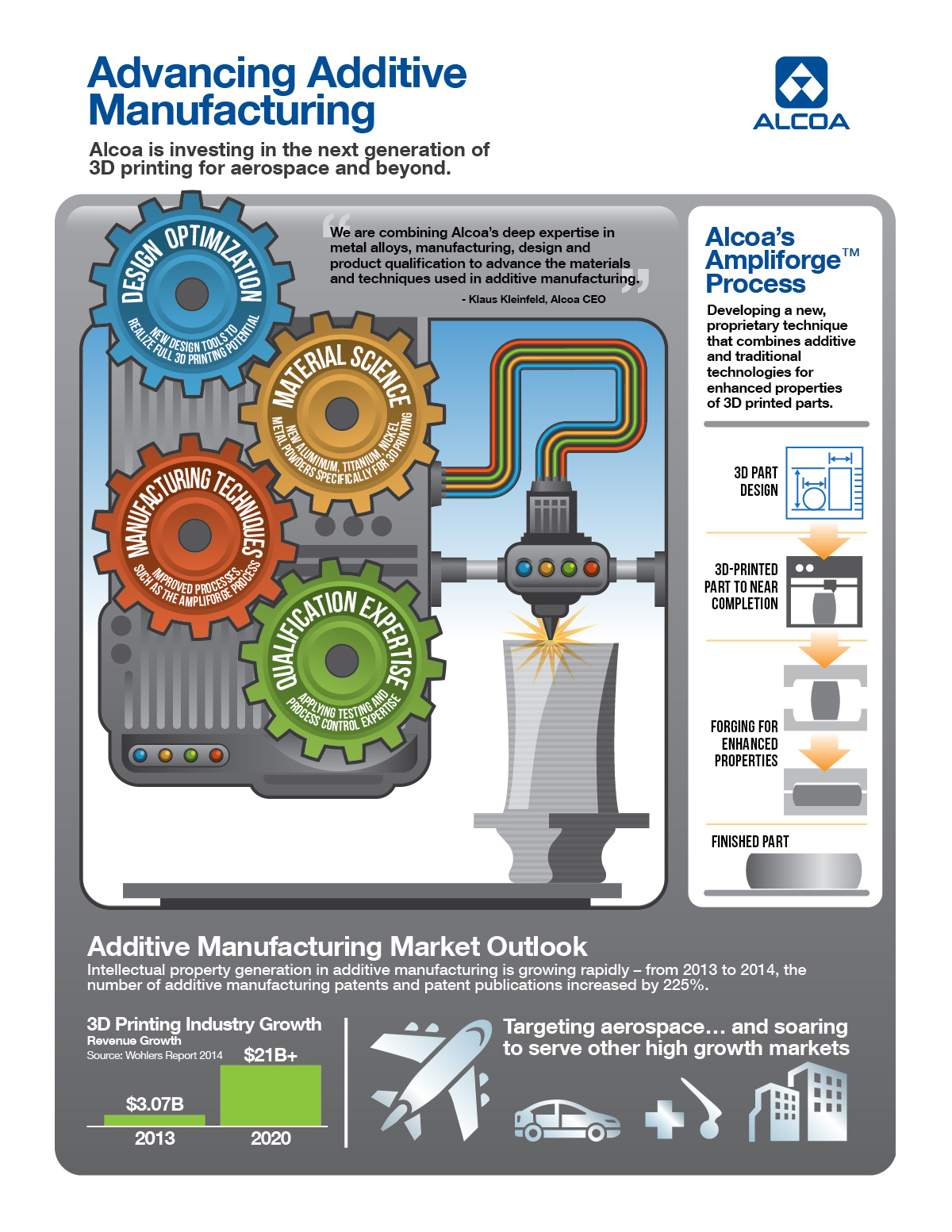

The world’s third largest producer of lightweight metals, Alcoa Inc., is expanding its R&D centre near Pittsburgh, Pennsylvania with an investment of $ 60 million to accelerate the development of advanced 3D printing materials and processes.

The company will produce materials specifically designed for additive manufacturing technologies to meet the growing demand for 3D printed parts in industries such as aerospace, automotive, medical as well as building and construction.

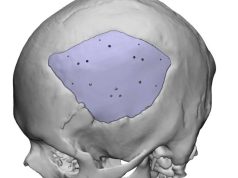

Alcoa also unveiled their proprietary Ampliforge process, a technique combining advanced materials and designs with additive and traditional manufacturing processes. Using this method 3D printed parts are treated with processes such as forging to enhance their properties, increasing toughness and strength. Moreover, it significantly reduces material input and simplifies production.

The company’s material scientists will develop 3D printing materials based on aluminium, titanium and nickel powders along with further developing the Ampliforge process.

The company’s material scientists will develop 3D printing materials based on aluminium, titanium and nickel powders along with further developing the Ampliforge process.

Alcoa CEO and chairman, Klaus Kleinfeld: “Alcoa is investing in the next generation of 3D printing for aerospace and beyond. Combining our expertise in metal alloys, manufacturing, design and product qualification, we will push beyond the limits of today’s additive manufacturing. This investment strengthens our leadership position in meeting fast-growing demand for aerospace components made using additive technologies.”

Construction work for the expansion has already started and is expected to be completed in the first quarter of 2016.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.