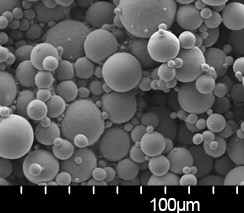

Canada-based subsidiary of Swedish metal additive manufacturing solutions company Arcam, AP&C, has filed a strategic patent application covering improved metal powder flowability.

AP&C has been producing high quality titanium and nickel super-alloy powders for AM applications for over 10 years, using their proprietary Plasma Atomization technology. The strategic patent application covers the use of this technology on different heated metal sources such as wire, rod and melt.

Jacques Mallette, President of AP&C explains in a recent press release: “The production yield is one of the key drivers to produce powder at low cost. The combination of high-yield of fine powder with a low gas to metal ratio of about 10 is unique to AP&C’s proprietary Plasma Atomization process.”

Arcam acquired the powder manufacturer AP&C from Raymor Industries for a total of CAD 35 million back in February of 2014. Earlier this year the company announced that it has completed the start up of its third reactor, adding significant capacity to its titanium powder manufacturing operation.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.