Roboze, supplier of additive manufacturing solutions, announces the start of the construction of a cutting-edge laboratory dedicated to the development of future super materials. The new 2000 sqm facility located in Bari, Italy, will aim to accelerate the transition to sustainable manufacturing and will add to the other already consolidated two offices of the company in the same territory, covering an area of over 5000 sqm completely dedicated to the development and engineering of the entire Roboze technological ecosystem: 3D printers, software and materials science.

The topic is hot, the attention and concern are high. Academic and industrial researchers around the world are working to devise solutions that can reduce consumption and dependence on fossil fuels, which are believed to be a major cause of climate change.

Roboze, manufacturer of one of the most precise 3D printers in the world specialized in the production of parts and components with super polymers and composite materials for metal replacement, has already demonstrated in the past its attention and commitment in the research and development of solutions that can reduce the environmental impact of manufacturing, but without sacrificing performance.

Starting from the overturning of the delocalized production model by proposing a new production paradigm, Roboze Distributed Manufacturing, in which specialized 3D printing centers with Roboze systems, distributed all over the world, produce parts wherever and whenever needed, reducing transport and waste, up to programs of Circular Economy for the recovery of processing waste and disused parts to be reintroduced on the market for the benefit of end users and above all the environment.

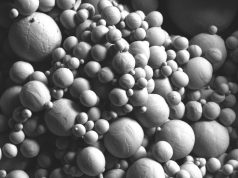

Today Roboze strengthens its commitment and invests in a facility that will host new material science, chemistry and nanotechnology laboratories. The goal is to rapidly advance in the development of alternative materials to petroleum-based super polymers by favoring the use of bio-based reinforcing matrices and fibers. The challenge lies in finding new materials and technologies that can, on the one hand, reduce the generation of carbon dioxide (responsible for the greenhouse effect), and on the other hand achieve the properties of the super polymers available today in the replacement of metal parts.

“Roboze is committed every day to developing the future super materials that will combine eco-sustainability with cutting-edge performance, with the aim of accelerating the transition to sustainable manufacturing.” declares Alessio Lorusso, Founder & CEO of Roboze.

In view of the lab’s launch, Roboze declares to open new positions in the engineering and scientific fields. The call is for 40 specialists to be hired over the next 18 months.

“We have a formidable team of scientists and engineers. We constantly question the status quo of what is thought feasible and what seems futuristic, giving a precise date to this second category. Our new laboratories will allow us to rapidly speed up all developments and will give us much more opportunities to invent what no one thought possible. Our challenge in Roboze is to create 3D printing technology and super materials for a paradigm shift in today’s production model, producing high-performance parts in a sustainable way, just in time and on demand, eliminating dependence on metals and oil ” concludes Lorusso.

Find out more about Roboze at roboze.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.