The initial hype around 3D printing has been overcome. Machines and materials have matured, and more and more industrial users are moving up the slope of enlightenment towards the plateau of productivity. While some companies are still struggling to implement additive manufacturing processes, others have managed to revolutionize entire markets with disruptive products. Surprising is the fact that the majority of companies have not even tried to herald the additive age, despite it promising many advantages. A view from the innovation management perspective will help to understand the phenomenon and to avoid common mistakes.

Dr. Johannes Gartner – February 18, 2020

Emerging vs. disruptive technologies

The terms emerging and disruptive technologies are often mistakenly used synonymously. While emerging technologies describe only innovations with the potential of being disruptive, real disruptions are only realized when an emerging technology is used to either solve an unsolved problem, or to solve an old problem in a better way. In scientific literature, such innovation processes are often described in the steps: Technology Recognition, Technology Adoption, Technology Acceptance, and Technology Usage.

From technology recognition to technology usage

The recognition of innovation represents the first major hurdle to overcome to benefit from new developments. It is, therefore, essential for strategic decision-makers to observe emerging innovations thoroughly and to evaluate them for possible adoption. In doing so, one should always look beyond one’s industry nose, since disruptions often come from foreign markets. Producing companies should therefore also examine other production paradigms such as forming, subtractive, and additive manufacturing processes. The same logic applies to materials, as materials science is one of the most vivid fields of research. Although many companies have a good overview of a familiar type of material, they regularly fail to evaluate developments in other types, be it metals, plastics, or ceramics. Once a potential new material or alternative process has been identified, the adoption starts through a conscious adoption decision of the strategic c-level management. The following acceptance process describes a change within the company and among the employees involved. This critical stage is highly dependent on the transfer of knowledge, the support received, the ability to rethink old patterns, and the individuals’ openness to new rules and possibilities. Since such transition often questions existing knowledge-based power structures within the company, this process must vigorously be accompanied by the c-level management to reduce resistance. The required patience and perseverance are regularly underestimated. This often results in delays or the inability to reach the final step – the technology usage and the actual value creation.

The long nose of innovation

This is very unfortunate since the majority of the investments have already been made, and the delay between adoption and value creation is already well known among scientists as the long nose of innovation . This “long nose” arises from the learning curve behind the implementation and has an important function. Once overcome, it protects early movers from rapid imitation and ensures a long-term competitive advantage. Furthermore, the potential of disruptive innovations can be more easily realized, and delays can drastically be reduced by collaborating with the right, experienced, and reliable partner through all stages of the innovation process.

Lithography-based ceramic manufacturing

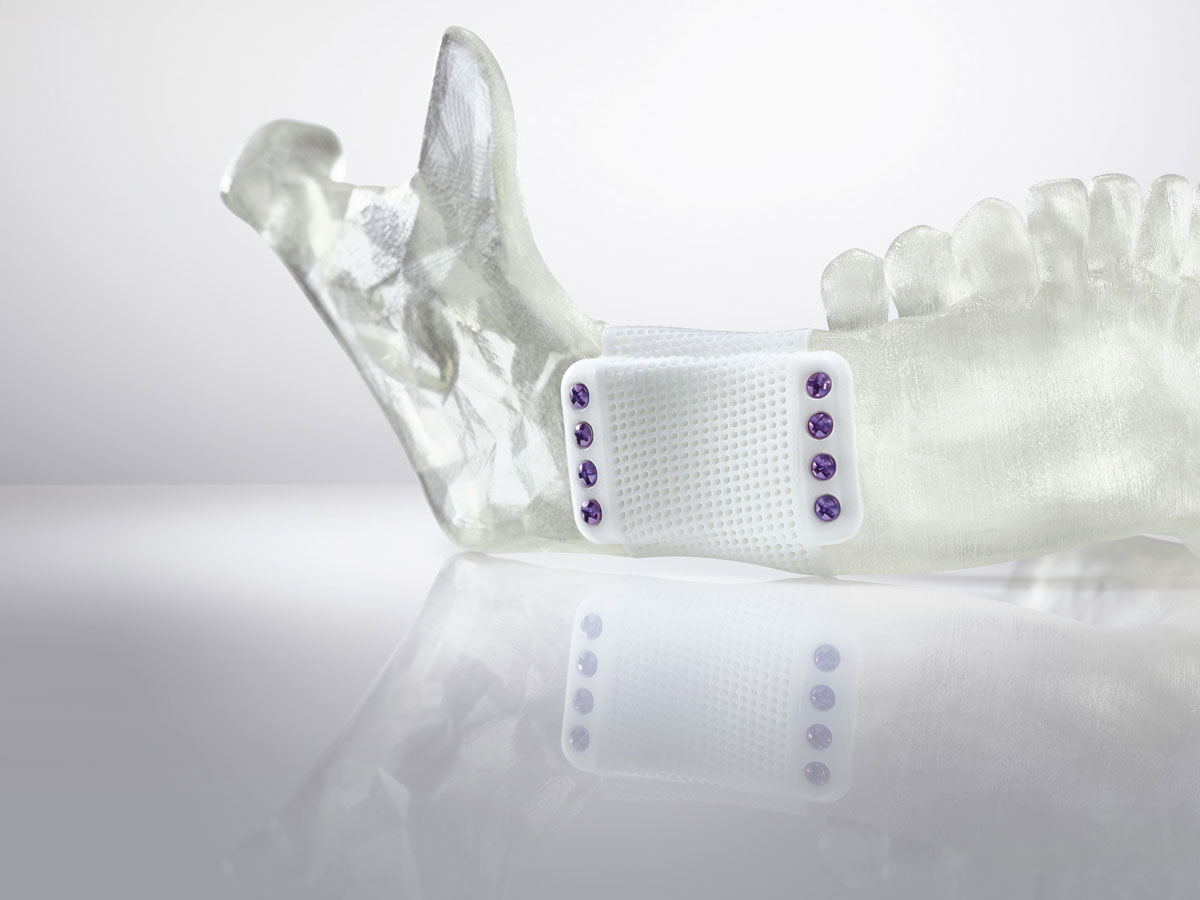

An ideal example represents the Austrian manufacturer Lithoz with its Lithography-based Ceramic Manufacturing (LCM) Technology. The company combines the advantages of additive manufacturing processes with the benefits of high-performance ceramics. Additive manufacturing processes enable a tool-free and resource-saving production of extremely complex structures that cannot be realized by other procedures. The digital 3D model allows rapid changes in the designs and automated creation of individualized parts. This results in shorter development times, the elimination of expensive moulds and thus helps to save time and money. Hence, additive manufacturing is increasingly used for the production of prototypes and individual parts in small, medium and large series often referred to as mass customization. The design freedom of the layered build process further finds applications in more function-oriented designs, such as to create internal structures, and to integrate several parts into one. Ceramics, on the other hand, have excellent properties on their own. Due to their excellent biocompatibility, ceramic materials are the materials of choice from metal-free dental restoration to bone replacement implants, without the disadvantages of releasing metal ions in human body. Their high-corrosion and high-temperature resistance also make ceramics a long-lasting material in harsh environments and is therefore the material of choice for many industrial applications. Lithoz’s LCM technology allows the production of very accurate ceramic objects with excellent surface qualities for a wide variety of disruptive applications. Such disruptive potentials are illustrated by 3D printed bioresorbable ceramic implants and ceramic casting cores.

3D printed bioresorbable ceramic implants

Severe bone defects can have different causes, from severe trauma, such as a fracture or bone resection due to bone tumours. They usually require an implant that is often harvested by autogenous bone graft processes. This treatment requires an additional surgery where a part of another bone, often from the iliac crest, is removed to form an implant from own tissue. Since each surgery imposes an additional risk for the patient, there is an urgent need for alternative bone replacement materials. 3D printed bioresorbable ceramic implants solve this problem. Bioresorbable ceramic has a very similar chemical composition to human bone and is printed in a porous structure that permits bone growth down into the channels. By slowly resorbing the ceramic implant, native bone tissue regrows, and an ideal healing effect without the need to remove the implant is achieved. In 2017, twenty craniomaxillofacial surgical procedures on humans were successfully performed.

Ceramic cores for turbine blades in aerospace and power generation

Lithoz’s LCM technology is also used for the production of the most recent casting core designs for turbine blades. Such cores have multiple layers of walls and branches, which cannot be produced by injection moulding. Thus, the options for introducing multi-vane, complex, and narrow cooling features in turbine blades is now possible. This carries revolutionary implications for more efficiency regarding the cooling of these blades, all the while, the high production speed of the Lithoz CeraFab 3D printers allows the final customer to receive the product in a reduced time.

Collaboration as success factor

These examples illustrate the disruptive potential that can arise from the combination of alternative processes and materials. Such innovation processes also require a reliable and competent partner who actively supports the implantation.

For further information please contact Lithoz GmbH at cc@lithoz.com or visit www.lithoz.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.