The Georgia Institute of Technology introduced the Focused Electron Beam Induced Deposition (FEBID) process which speeds-up the printing of 3D nanostructures.

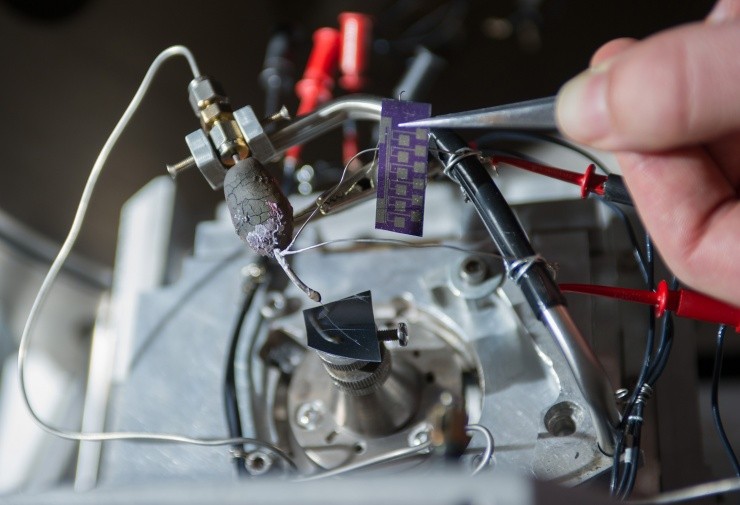

The FEBID system uses a beam of high energy electrons and a jet of thermally excited precursor gas to realize a fast direct-printing method.

The process focuses the beam and the gas within a particular spot on a substrate. Through a micro-capillary injector of the size of few micrometres, tiny jets of gaseous molecules are accelerated to supersonic speed. The supersonic speed helps to break up the chemical bond between the electrons to speeds up the printing process. The molecules adsorb to the substrate and are controlled deposited to create complex 3D nanostructures.

By further observing the exponential amplification of the molecule transport and the rate of reaction, the researchers developed a new theory about this nano printing technique. To better understand the phenomena, the researchers had to develop a nanoscale thermometric model to predict the adsorbed atoms effective-, and surface- temperature in response to the supersonic impingement. They discovered a new state of radical thermal non-equilibrium in surface adsorbed molecules, which allows the faster surface diffusion and therefore printing of energized adsorbed atoms without changing the substrate surface temperature. A change of the effective temperature of the adsorbed atoms allows the control of the surface diffusion rate. These findings could enable a whole range of new nanoscale manufacturing processes that depend on surface diffusion of precursor molecules such as magnetic memory, superconducting materials, quantum devices, and 3D electronic circuitry.

In a future study, the researchers plan to apply hybrid jets consisting of a high-energy inert gas and precursor gases to control the material composition during 3D printing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.