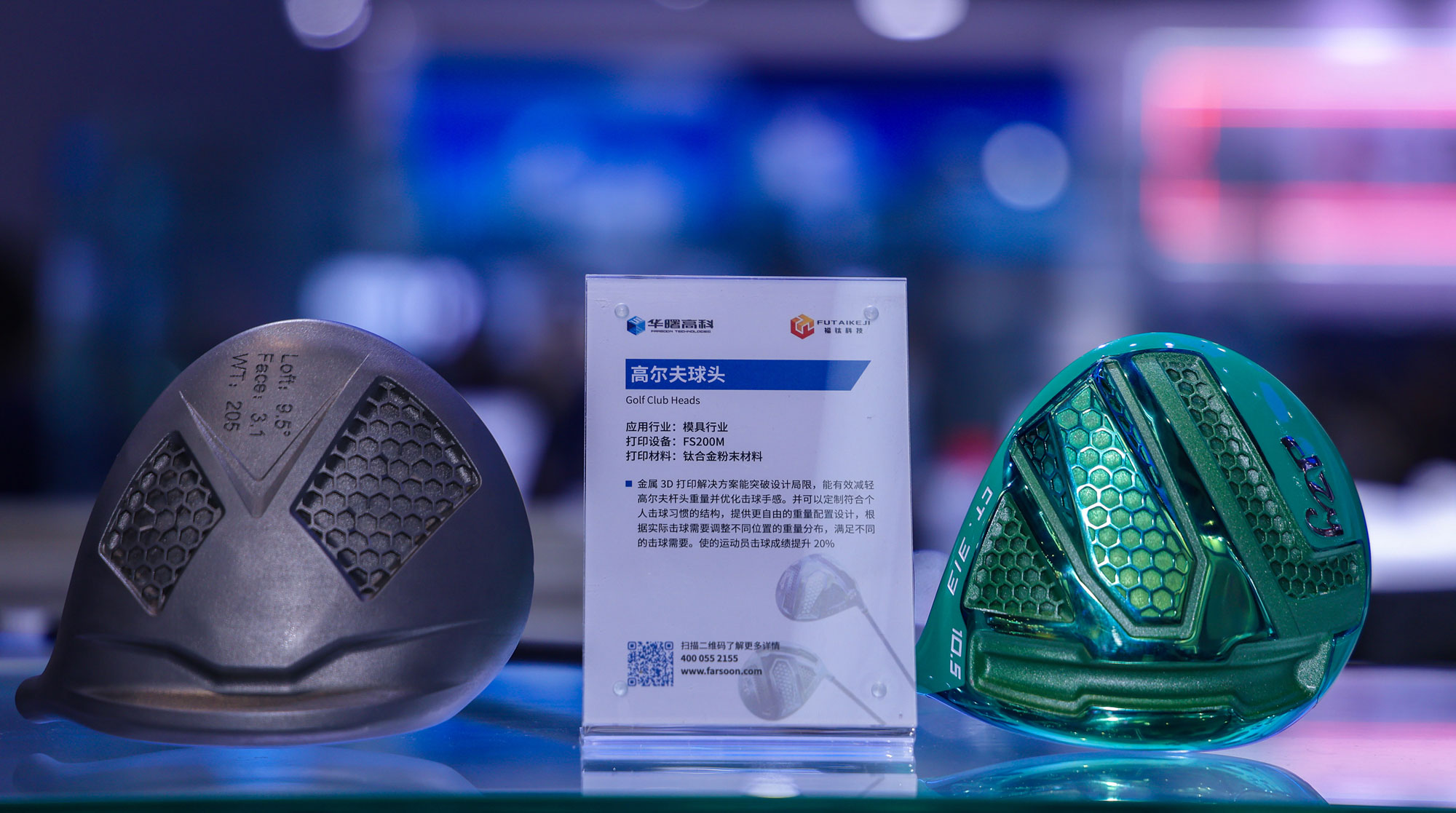

The Chinese company Futai Technology uses 3D metal printing to produce customized golf club heads from titanium alloys. Using multiple systems from Farsoon, the company is able to produce more than 15,000 club heads annually.

According to Futai, additive manufacturing enables economical production of personalized designs with optimized shapes and weight. Using a special lattice design, the 3D-printed rackets have increased strength and performance.

In the consumer goods sector, the pressure to produce efficiently is great. Here, 3D printing can help achieve material savings, according to Futai. In addition to cost benefits, he said, this also favors more environmentally friendly manufacturing.

Additive manufacturing has great potential to make manufacturing more sustainable, he said. Material consumption in particular will play an important role in the eco-balance in the future. With the help of 3D printing, lightweight construction and material savings can be ideally combined through targeted design, according to the company.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.